The devastating effect of water on your lube oil additives

BioKem recently completed a lubrication purification role at one of Australia’s large coal-fired power stations. BioKem had previously assisted the Plant during a shutdown; however this call was urgent due to a significant anomaly occurring in one of their Steam (Boiler) Feed Pump oil tanks.

Lubricant: Caltex Regal R&O 32

The Problem

| In-house lube oil lab reports revealed an ISO 4406 trend of 20/18/14 (NAS 9) over a 12-month period, peaking at 22/19/15 (NAS 11) when they flagged it. This is definitely out of spec for a Steam Feed Pump lube tank, even using a Group 1 mineral oil. A large quantity of sludge was removed from the on-board strainers. It was later determined that the on-board filtration and coalescer system was not working correctly and the filter housings also held a lot of sludge. The site had already had a failure of a $28,000 control valve system that was suspected to be from the contaminated oil and continued operation of the unit in this state, was a concern. |  |

The Challenge

The main consideration from the Plant engineering team was to stay online and correct the contamination problem ASAP. A reasonable solution could have been to dump the oil and refresh the lube system with a fresh charge of 7,000 of oil. This would have involved the unit being offline so was not preferred! Also, filling with (new) unpolished oil, which is supplied nominally around 21/18/15 (NAS 10) was not going to help.

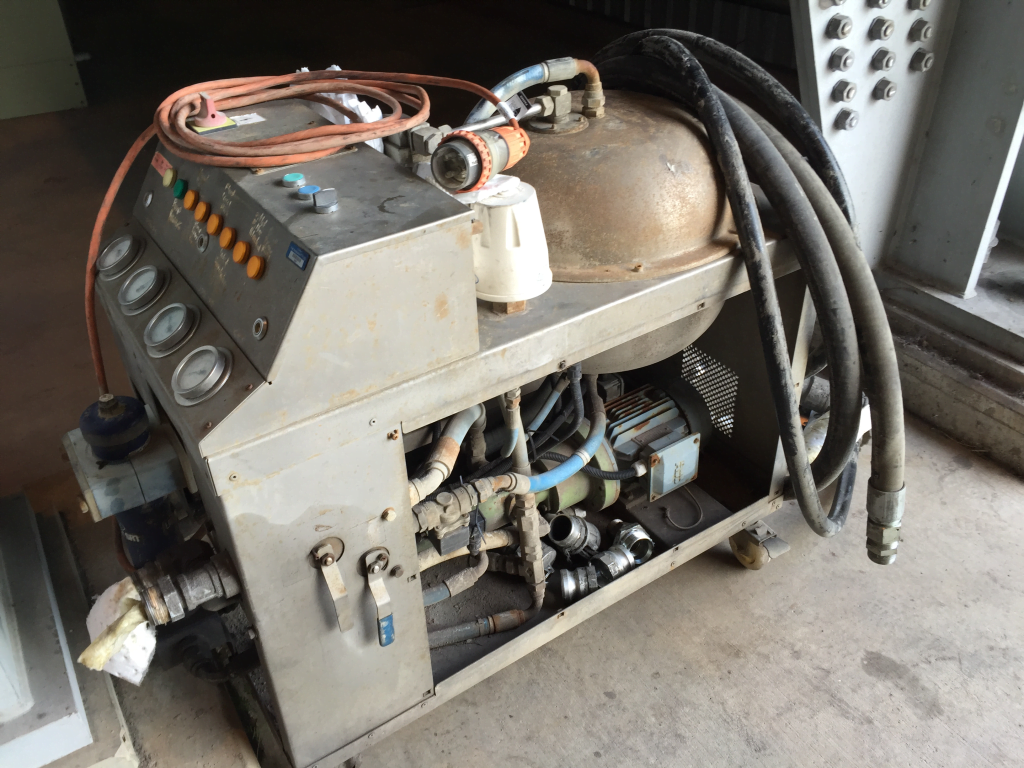

Considering the urgent nature of the project, BioKem mobilised on a Sunday, to be onsite 6:00 am Monday morning, completing safety inductions and site requirements. We deployed a low profile 140l/min Vacuum Dehydration Oil Purification System (VDOPS) suited for this constrained environment.

Tasked with correcting the SFPT lube oil ISO 4406, and identifying the contaminants, BioKem established a mobile laboratory to patch test samples whilst onsite.

An additional challenge was the tank ports, at 1” diameter, that were too small to flow the required 140 LPM of our purification rig which has 2” connections.

The Solution

The BioKem VDOPS rig, with a flow capacity of 140 LPM or 8,400l/hr, vacuum dehydration, 2 µm filtration, centrifuge and heating. The compact design and low profile of this rig allow us to stage it right next to the Boiler Feed Pump Tank.

Purification Tasks

For the 7,000l tank, circulating at 140 LPM, a complete cycle is every 50 minutes, we estimated up to three days of purification, operating 24hrs, to correct the ISO 4406 from 22/19/15 (NAS 11), to a healthy 16/14/12 (NAS 5).

Summary of Results

We reached our target ISO of 16/14/11 (NAS 5) in less than two days of purification, however the onsite lab tests we conducted revealed another problem that would need addressing. The strainers had collected ‘orange flakes’ and this confirmed our visual inspection of the lube tank showing a coating of varnish. The varnish was probably caused by a previous water event as water can strip oil of antioxidants and leave an unwanted deposit on surfaces in the lube system.

Analysis of Contaminants

An oil sample was taken and an MPC test gave a result of 23 which is an indication of soft contaminants in the oil. These soft contaminants cannot be filtered out with standard particle filtration as they are in solution. They do however have a tendency to plate out on cooler surfaces such as heat exchangers, tanks and oil coolers and a plan is needed to resolve this problem. A chemical additive such as Boost VR or Exxon System Cleaner prior to Electro Physical Separation (ESP) can be used and a tailored solution would be needed to fix this Boiler Feed Pump lube circuit. Click on the links for more information.

Post-Purification Strategy

After the varnish problem is resolved then fresh, filtered oil will provide the unit with the much needed additives that were depleted by the water event.

Success Metrics

- The unit was able to stay online.

- The oil cleanliness was reduced 6 NAS Codes, by removing a significant quantity of metallic debris, silica, rust, fibres, and asphaltenes.

- A previous undetected problem of oil varnishing of the tank and circuitry was identified. Incidentally, had the oil been discarded and replaced then this problem may have become worse as the new oil plated out the varnish into bearings and circuitry.

Cost Benefit Analysis

Our service saved our client the cost of shutting down and starting up the feed pump, the loss of revenue for those hours, the disruption to services, customer goodwill, the cost of replacement lube oil at $15,000, the potential costs of future breakdowns and equipment failure and the cost of wages and salaries at an unknown but significant cost.

Conclusion

In summary, our clients faced losses many times the cost of our services. These savings prove once again that unplanned maintenance costs are at least seven times the intelligent maintenance costs. It doesn’t get much better than this!

Photo Essay

View of sludge in on-board conditioning filtration |

ISO Patch Tests at 100X mag before filtration |

Before Filtration ISO 4406 21/19/16 (NAS 10) |

ISO Patch Tests after filtration at 100x mag |

After filtration ISO 4406 16/14/12 (NAS 5) |

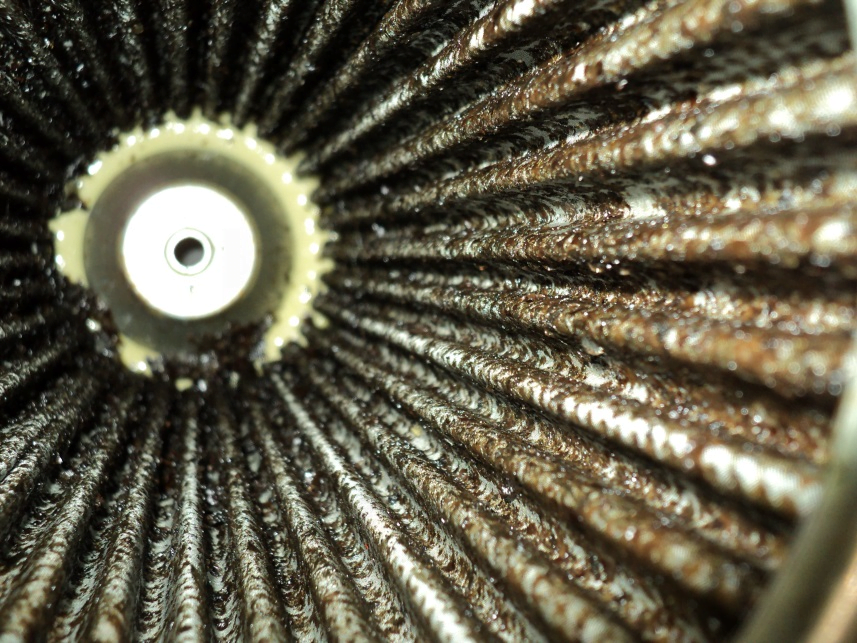

Inside of 120μm strainer showing varnish ‘flakes’ |

The same varnish flakes washed out into a tray for inspection (there was more than this!) |

Site portable filtration solution struggled to manage the problem |

Should you require professional services to filter or handle your circuitry, spools, coolers, lube tanks, or manifolds, please contact us.