Use this 13 Point Checklist To Double Your Equipment Life

Here is your checklist to use or direct to your staff…

Checklist

- Are breathers installed on all our lube tanks?

- Are all breathers maintained on a schedule & desiccant shows correct colour?

- Are our staff trained to take oil samples and the same ports used every time?

- Is a regular sampling and laboratory program in place?

- Are laboratory reports being analysed by our staff and results understood?

- Is our lube room clean and products well labelled?

- Do we have a lube storage management system?

- Are oil stocks kept in a dry cool setting out of direct sunlight?

- Is lube transfer equipment (pumps/funnels/hoses) clean?

- Is free water drained from lube tanks on a scheduled basis?

- Do we always us the same brand and type of oil for top-ups?

- Is filter media monitored by differential pressure gauges/schedule?

- Are differential pressure gauges calibrated?

If your team can tick each point above then you have achieved a significant and very affordable step towards lubrication excellence and your machinery life will benefit.

Extending Machine Life through your Oil

Getting the most out of your lube oil, without compromising your rotational equipment, makes sense. The cleaner your lube oil, the longer the life of your equipment, this is a direct correlation.

Let’s start with what degrades lubricants…

Wear Particles

Wear particles can score and attack sensitive components, accelerating wear rates. Byproduct wear elements such as iron, chromium, aluminum, copper, lead, tin, antimony, silver, manganese, and titanium commonly indicate component wear. The presence of wear particles has a compounding effect further loading the lube oil and damaging the machinery components. Some wear debris will also oxidise to deplete the antioxidant additive package in your oil, leading to corrosion and rust.

Moisture

Water/moisture contamination in your lube oil has a degrading effect on lube oil, additives and your machine. Water exists in oil in three states, free, emulsified and dissolved. Free water separates and forms pools at the bottom of the tank. Emulsified is where your oil looks milky. Free and emulsified water pose the greatest threat to the machine. Some additives will cling to the oil and can end up being removed when the water separates from the oil (water washing), other additives are destroyed through oxidation and hydrolysis.

Gas Contamination

Gas contamination has a similar effect as moisture and is detrimental to the effectiveness of the lube oil, as it can alter viscosity, deplete antioxidants and critically lower the flash point of your lube oil, causing a dangerous explosive environment. (We have seen flash points drop to as low as 40°C from gas contamination)

Dump and Replace?

In the event your lube oil suffers a contamination event, most often it can be ‘rescued’ rather than dumping and replacing the oil. Fine filtration with either high quality filter media or depth media will resolve the particulate loading. Vacuum dehydration is the best form of moisture and gas removal from oil, either as a service or a fulltime application if the problem is chronic.

What should you do?

The following tips will increase your lube oil service life:

- Fit breathers to your tank vents and establish a program to maintain them. In dry environments a 3µm particle filter will prevent the ingression of fine particulates. For humid environments, install a good-quality desiccant breather.

- Establish a regular oil analysis program. You can ascertain and trend results, monitor the condition of your oil, add additive packages as required and get early warning of impending failures.

- Check external seals for damage or buildup of grime leading to ingress.

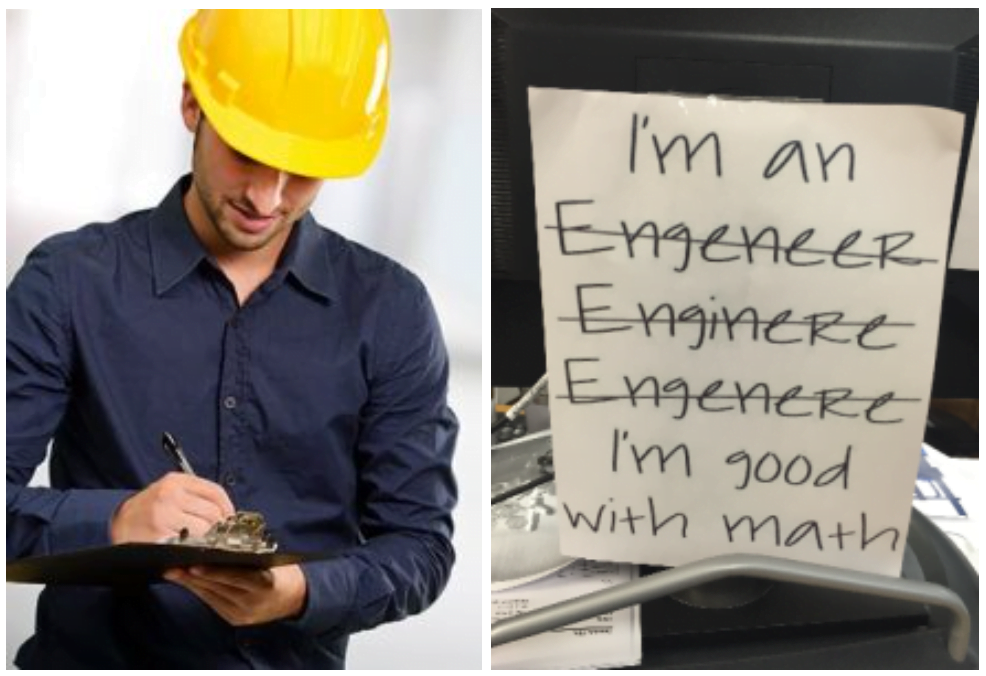

- Practice clean lube room operations, ensure all oil containers are sealed, clean all equipment used in the top-up process. Implement an oil storage management system as common sense isn’t that common.

- Never cross contaminate make-up or top-up lubes, always use the same brand and type when topping up. Sweetening or topping up lube oil has the added benefit of improving oil additive pack levels (new oil has high levels of additive).

- Implement a well thought out sample, test & analysis program suitable for your machinery application, and study the results and trends.

If you would like further information on this article or others, please feel free to contact us.