Lubrication technology has advanced significantly with the introduction of synthetic oils. But while synthetic oils offer various advantages, they might not always be the best fit for every situation. Let’s explore some important considerations for synthetic oils compared to traditional mineral oils.

In Our Last Article: The Advantages of Synthetic Oils

In our previous article, we discussed the numerous advantages of synthetic oils over mineral oils, including better efficiency, thermal stability, and resistance to degradation. While these benefits may sound promising, it’s essential to weigh them against the unique needs of your application. The advantages of synthetic oils might not always be fully realised in every situation.

Sticking With Mineral Oils: When Synthetic Oils May Not Be the Best Option

The conditions in which the lubricating fluid is used play a significant role in determining whether switching to synthetic oil is the best choice. Consider these important factors before making the switch:

-

Seal Compatibility

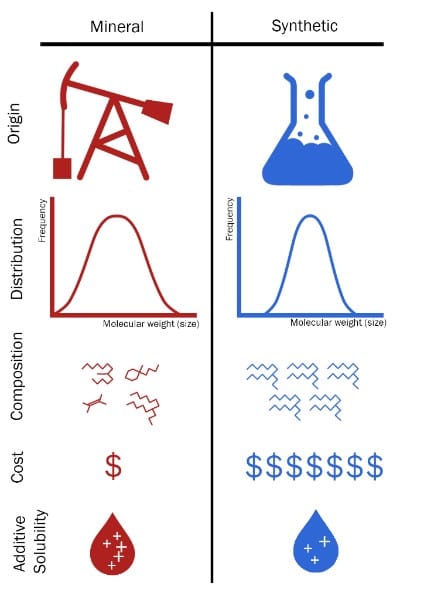

One potential concern when switching to synthetic oils is seal compatibility. Some users have reported increased oil leakage after switching from mineral oils to synthetics. Ester-based synthetic oils may not be compatible with certain types of seals, leading to slow degradation. The streamlined molecular structure of synthetic oils also makes them more prone to leakage, especially if seals don’t properly swell as they do with conventional oils.

-

Solubility of Additives

In high-demand machinery, oils need specific additives like extreme pressure (EP), wear inhibitors, and rust protectants to maintain performance. The chemical structure of synthetic oils can sometimes make it difficult for these additives to dissolve properly, potentially affecting the lubricant’s ability to perform in extreme conditions. This could be a consideration when choosing synthetic oils for equipment requiring specialised protection.

-

Cost Considerations

One of the most significant considerations when switching to synthetic oils is the price. Synthetic oils can be four to fifteen times more expensive than mineral oils per barrel. This price difference makes the transition to synthetics a significant financial commitment. Additionally, you may face higher costs if seals need to be replaced due to incompatibility with synthetic oil.

-

Could Synthetic Oil Be Unnecessary?

Although synthetic oils offer impressive properties such as enhanced thermal stability and efficiency, these advantages may not always be fully utilized in every application. For example, if your equipment does not operate in extreme temperatures or under high-stress conditions, the additional cost of synthetic oil might not provide significant benefits. In such cases, mineral oils might serve your needs just as effectively at a lower cost.

Conclusion: Is Switching to Synthetic Oil the Right Decision for You?

While synthetic oils offer excellent performance in areas such as thermal stability, resistance to wear, and oxidation, the higher cost is a key factor to consider. Depending on your equipment’s specific needs and operating conditions, synthetic oils might not always be necessary. If your mineral oil is performing well and the operating environment does not require the added benefits of synthetics, switching may not be justified.

However, if you anticipate operating in extreme conditions or want the potential for longer oil life, synthetic oils may be a worthwhile investment.

Ultimately, a careful analysis of your system’s needs is crucial to determining if synthetic oils are the best choice for your application.