Optimise Equipment Performance & Extend Machinery Life with BioKem

In industrial settings, lubricants are the lifeblood of your machinery, ensuring smooth operation, efficiency, and protection against wear. Just like a medical blood test offers vital insights into health, BioKem’s lube oil analysis assesses the health of your machinery through precise testing and detailed reporting. Our services help you catch early signs of contamination, wear, or lubricant degradation, allowing you to protect your equipment and manage maintenance costs effectively.

Why Lube Oil Analysis?

Lube oil analysis identifies critical indicators within the oil, offering insights into potential problems and the overall health of your equipment. By understanding your oil’s condition, you can prevent costly breakdowns, extend machinery life, and enhance efficiency. This proactive approach ensures you stay ahead of potential issues by comparing current oil conditions with historical data to track changes over time.

Comprehensive Lube Oil Analysis Services

At BioKem, we offer an array of lube oil analysis solutions to meet your needs, from standard testing to specialised varnish analysis:

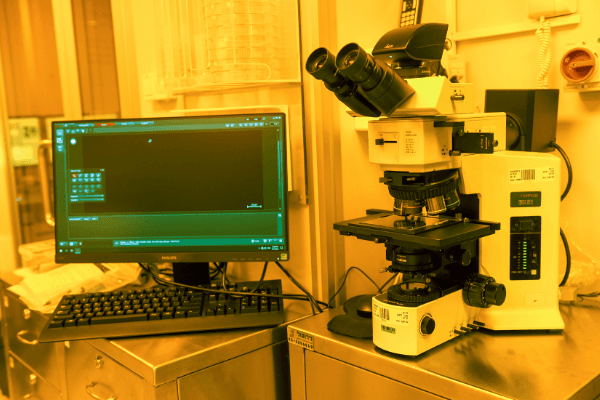

- Sample Collection & Reliable Testing: We provide high-quality sampling bottles and arrange lab tests with verified accuracy, ensuring dependable results every time.

- Detailed Reports & Expert Recommendations: Each analysis comes with an in-depth report covering key findings, trend analysis, and actionable recommendations, helping you make informed maintenance decisions.

- Advanced Varnish Testing: Our varnish tests include wear debris analysis and photographic documentation to detect and address potential risks before they become costly issues.

Specialised Testing Options for Every Need

BioKem offers customisable testing options to meet specific operational requirements:

- Comprehensive Oil Health Analysis: A full spectrum of tests to assess overall oil condition and longevity.

- Standard Oil Testing: Routine testing to monitor oil health and contamination levels.

- Compatibility Testing: Ensures your equipment’s safety by confirming the compatibility of oils across various machinery components.

Partner with BioKem for Proactive Machinery Maintenance

Take control of your machinery’s health with BioKem’s lube oil analysis services. From reducing unplanned downtime to extending equipment life, BioKem empowers you to maintain peak performance. Our expert team and state-of-the-art testing services make it easy to address issues before they escalate, keeping your operations efficient and cost-effective.

Lubrication Oil Filtration

Lubricants in modern close tolerance rotational assets are designed to do several things aside from reduce friction. Lubricants also carry away wear debris, reduce temperature, impede corrosion, and transmit power.

MoreMicrobial Contamination of Lube Oil

Just like you, your lubrication fluid can get sick. Bacterial infestation of lube oil can be a huge problem.

MoreFuel Filtration

BioKem Oil Services conducts commissioning roles for newly fabricated lines ensuring that new pipework is clean and ready to receive fuel.

More