Analytical Ferrography (and Wear Debris Analysis) can be viewed as the oil analysis equivalent of CSI forensic science. The wear debris separation is different to WDA test method with the ferrous wear debris in the sample magnetically extracted and deposited on a microscope slide called a Ferrogram enabling a visual, microscopic evaluation of the contaminants separated.

Ferrograms are able to be heat treated which forces oxidation colours from the metallic wear debris providing a fast accurate identification of the different types of metal wearing abnormally in the machine sampled.

BioKem Oil Services uses Ferrography as one of their fundamental tools for analysing used oil and grease samples with the results used to improve the customers equipment overall reliability. In the hands of our experienced analysts, Analytical Ferrography is capable of detecting active machine wear and help provide a “root cause” conclusion based on the morphology of the wear particles.

Due to the method of sample preparation, Analytical Ferrography is biased but not necessarily limited to ferrous particles. By combining Analytical Ferrography with other particle separation and analysis tests the results are capable of determining the Root Cause of:

- Abnormal wear commencement in drives, transmissions, hydraulics and engines,

- Root cause of wear preventing wear failures in drives, transmissions, hydraulics and engines,

- The different component(s) wearing in drives, transmissions, hydraulics and engines,

- The Lubricant condition and suitability of running lubricants beyond their rated life,

- With blowers and compressors; the efficiency and condition of main induction filters

- With combustion engines; the quality of combustion and efficiency of main induction filters

- With turbine fluids degradation of turbine fluid as polar components from the damaged fluid deposit in the magnetic field.

- The types of inorganic contaminants gaining ingress into the oil lubricated area of the plant item being sampled.

- Separation of ferrous and nonferrous contaminants from grease samples.

- Separation of ferrous and nonferrous contaminants from oil filter media.

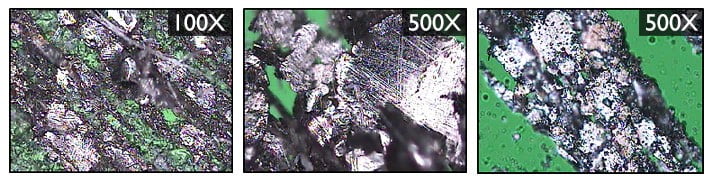

Ferrogram – Heavy Wear ——— (100 µm @100X, 20 µm @500X)

Ferrogram – Moderate Fine Wear ——— (100 µm @100X, 20 µm @500X)

Ferrogram – Light Wear ——— (100 µm @100X, 20 µm @500X)

Ferrogram – Crystalline Contaminates ——— (100 µm @100X, 20 µm @500X)

To differentiate between high alloy wear debris, bearing wear, and low alloy wear debris, gear wear, the ferrogram was heat treated in the furnace, the heat treatment forces oxidation of the metals in the wear debris.

Low Alloy Steel wear debris oxidises blue.

High Alloy Steel wear debris oxidises purple orange red.

Ferrogram – Heat Treated ——— (20 µm @500X)

Lubrication Oil Filtration

Lubricants in modern close tolerance rotational assets are designed to do several things aside from reduce friction. Lubricants also carry away wear debris, reduce temperature, impede corrosion, and transmit power.

MoreVacuum Dehydration Oil Purification System

Our Vacuum Dehydration Oil Purification System (VDOPS) is manufactured in the USA and is the gold-standard for oil purification today. It exceeds outcomes delivered by equivalent centrifugal process systems at removing all forms of moisture,

MoreCommissioning and Shutdowns/Turnaround

BioKem Oil Services attends site to assist our clients and constructors to achieve maximum equipment reliability while also minimizing unscheduled future downtime to their lubrication oil.

More