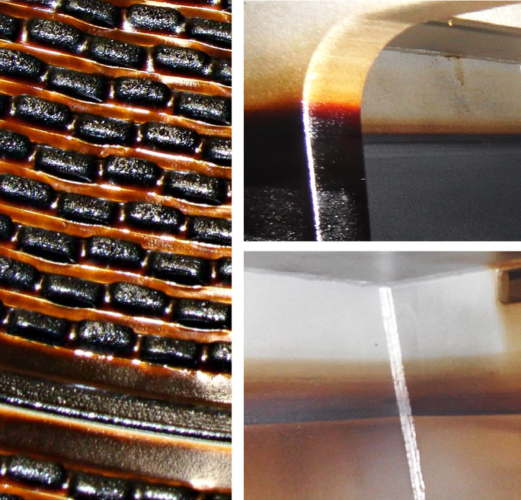

Varnish can be formed by many different events, from gaseous product ingression in compressors, stress of the oil due to high temperatures (hot spots), incorrect selection of lubricant, and more. Varnish is formed as the additive pack is used up doing its job and waste is formed from the depleted antioxidant package.

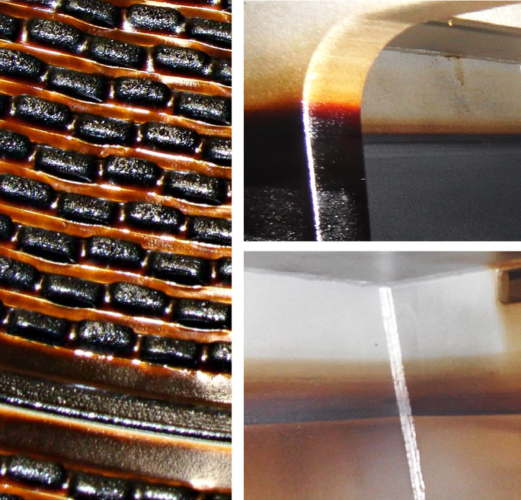

Removing the varnish in bulk can be achieved at the time of an engine pack change or during an outage. This is best tackled using a specialised chemical system cleaner. There are a number of proprietary products on the market, that work in similar ways by solubilizing the varnish deposits within the system.

There is a routine to follow for effective treatment with the best way to remove the bulk of the solubilised varnish being to dump the existing oil charge to waste.

Even once that’s conducted, a detailed confined space clean will also be required and high velocity flushing essential to remove any legacy contaminants from the system before recommencing operations.

Lube oil varnish can be formed by different players, from gaseous product ingression in compressors, the presence of moisture in the lube oil, stress on the oil due to high temperatures (hot spots), incorrect selection of lubricant or viscosity, and many more.

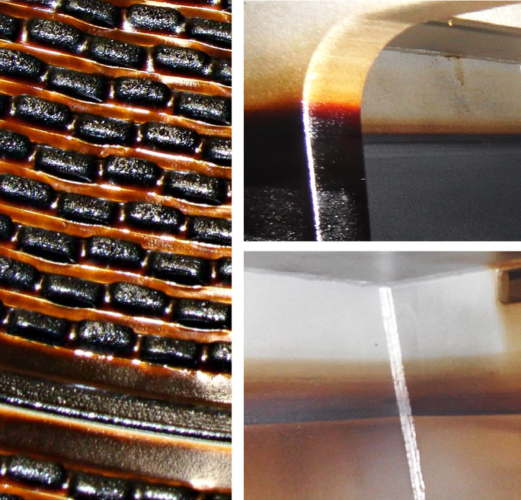

Varnish in oil is formed as the additive pack is depleted and waste accumulates from the depleted antioxidant package. Oil degradation or oil oxidation results in plated sticky varnish in the system impacting clearances particularly on control systems and servo valves.

Removing the oil varnish in lubricants can be achieved during a programmed shut or post failure event. When an MPC test (Membrane Patch Colorimetry) detects varnish potential, there are several methods for effective lube oil varnish removal.

The MPC oil test is the beginning of the process, and the solution may require a varnish removal system (VRS), the use of additives, cleaners, or a detailed confined space clean.

BioKem has a hire fleet of varnish removal systems (VRS) to deal with Varnish removal. https://biokem.com.au/varnish-removal-system/

Varnish removal in lube oil systems can manage light varnishing whilst the asset remains on duty. BioKem also utilises a variety of cleaning agents suited to deal with oil varnishing and to solubilise varnish. Common brands are Mobil System Cleaner (MSC), also known as Exxon System Cleaner, Fluitec product such as Boost VR, Kluber Summit Varnasolv and Chevron Vartech & others.

The selection of a suitable products is critical, and dependent on the system size, type of varnish present and lubricant system design.

Managing vanish potential in lube oil requires planning and cannot be resolved by simply dumping the new oil to waste and introducing a new fresh change of oil. This activity can exacerbate the problem and accelerate oil degradation in the new oil charge!

Even once a chemical treatment has been conducted, a detailed confined space clean will also be required and high velocity flushing essential to remove any legacy contaminants from the system before recommencing operations. There are also strategies we can help with to improve varnish prevention.

For more information see our detailed ‘Varnish in Lube Oil’ page https://biokem.com.au/service/varnish-in-lube-oil/

If you require assistance with treating a heavily varnished system for an upcoming outage or maintenance, give us a call first and we can guide you through the process and provide products and services as needed.