|

For living beings, water is life, but for your compression assets, moisture damage in compressors can cause severe operational issues. This article explores how moisture infiltrates lube oil, the damage it inflicts, and practical steps to mitigate its impact. |

How Moisture Damage in Compressors Happens

-

Process Gas Streams

When extracting process gases, water often tags along. Imperfect seals allow moisture to transfer into your lube oil, causing moisture damage in compressors.

-

The Environment

Humidity and exposure to environmental air contribute to moisture infiltration. Improperly configured lube oil tanks exacerbate the problem. Processes like filling, draining, or thermal expansion pull in damp air, leading to rapid degradation of oil.

Effects of Moisture Damage in Compressors

There are many detrimental effects of having water present in your oil. Here are a few that will potentially deal the most damage:

-

Hydrogen Embrittlement

High pressures split water into hydrogen and oxygen, diffusing hydrogen into metal surfaces. Over time, this causes cracks and catastrophic compressor failure.

A crack in metal alloy caused by hydrogen embrittlement.

-

Steam Micro-Explosions

When dissolved water undergoes rapid pressure changes, it vaporizes explosively, leading to pitted surfaces and reduced oil effectiveness.

-

Impaired Lubrication Ability

Moisture disrupts oil viscosity, leading to insufficient lubrication and potential mechanical damage.

-

Accelerated Varnish Formation

Moisture depletes antioxidants in oil, accelerating varnish build-up and causing component failures.

-

Sludge Formation

Water binds with polar contaminants like soot and oxides, forming sludge that clogs oil pathways.

-

Corrosion

Water reacts with acids to corrode surfaces, reducing oil film strength and exacerbating wear.

A combination of heavy damage by cavitation and corrosion on turbine blades.

What Can You Do About It?

1. Isolate Your Oil from Process Gas

If possible, remove all moisture from process gases before compression or isolate bearings completely. However, this solution can be challenging to implement.

2. Prevent Environmental Moisture Ingress

2. Prevent Environmental Moisture Ingress

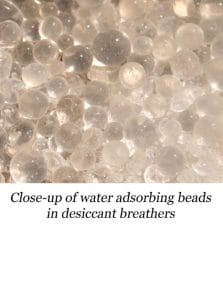

Install a desiccant breather on your lube tank to filter out airborne moisture and particles effectively.

3. Remove Moisture from the Oil

For significant contamination, vacuum dehydrators are the best solution. These systems remove water and entrained gases efficiently, keeping your oil dry and clean. Installing a vacuum dehydrator in a kidney loop can provide continuous protection.

- How Vacuum Dehydrators Work

These systems combine heat and vacuum pressure to evaporate and eliminate water from the oil. They also extract entrained gases, often introduced by process gases carrying moisture. This approach ensures all forms of water are thoroughly removed, keeping your oil in optimal condition.

- Benefits of Vacuum Dehydrators

Attaching a vacuum dehydrator permanently to a lube tank in a kidney loop system ensures long-term moisture management. This cost-effective solution prevents moisture-related damage, extending the lifespan of your lubricant while ensuring it remains clean, dry, and effective.

Summary

Moisture damage in compressors can lead to varnish, corrosion, sludge, and more. Addressing this issue with desiccant breathers and vacuum dehydrators ensures long-lasting equipment performance. Don’t let moisture compromise your compressors—take action today.

If you would like further information on this article or others, please feel free to contact us.