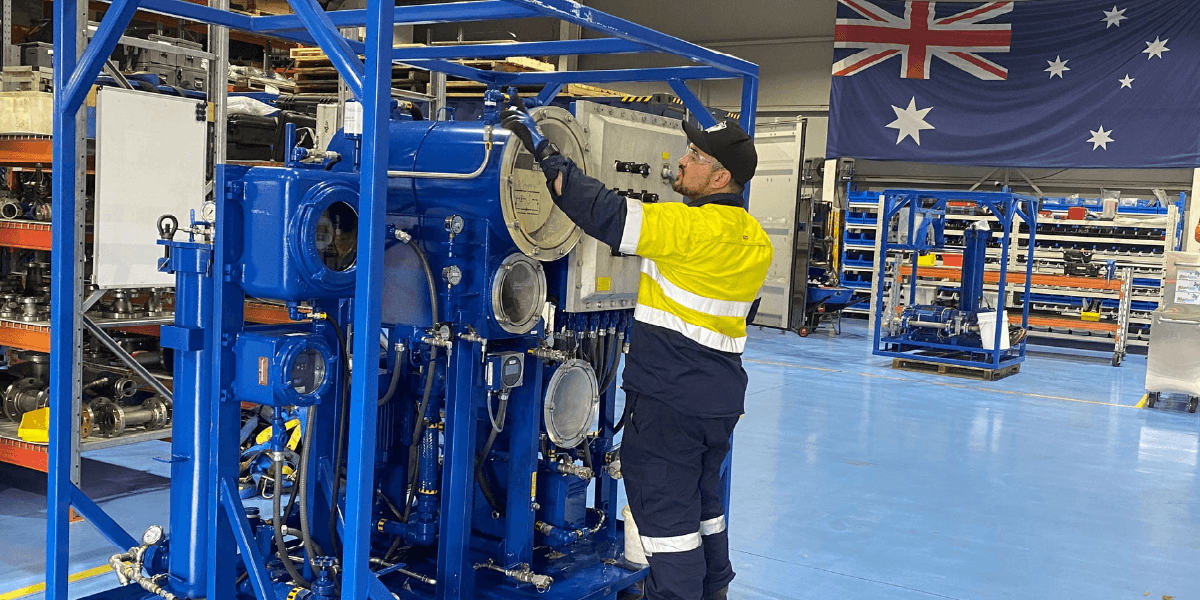

Reclaim used hydraulic oil efficiently with VDOPS to reduce waste, lower disposal costs, save money, and meet OEM cleanliness standards.

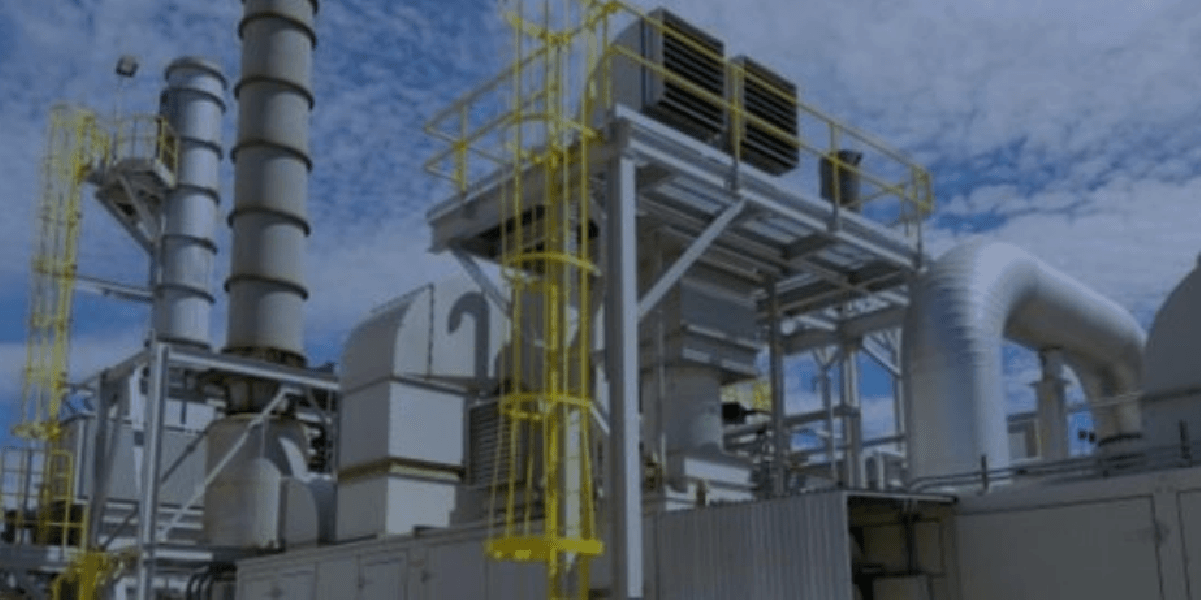

Case Study: Particulate, Water, and Varnish Contamination in Gas Compressor

BioKem tackles gas compressor oil contamination, removing particulates, water, and varnish for improved performance.

Case Study: Entrained Gas Contamination in Lube Oil System

Introduction

At a major petrochemical facility, a gas compressor’s lube oil system became contaminated with acetylene gas due to a leaking seal. The 3,000L system faced severe risks as light-end hydrocarbon gases – including H₂S, benzene, toluene, and acetylene – lowered the oil’s flashpoint and negatively impacted the viscosity of the ISO VG 32 compressor oil, making it ineffective as a lubricant.

The Problem

Shutting down the compressor to repair the leak would have resulted in major downtime and excessive cost. Instead, plant operators resorted to “sweetening” the oil—adding new oil through the fill port and draining the contaminated oil from the bottom. This ongoing process cost approximately:

-

$67,500 per month in new oil

-

$800,000 annually, excluding labour costs

Despite the effort, the entrained gas contamination in the lube oil system continued to compromise safety and performance.

The BioKem Solution

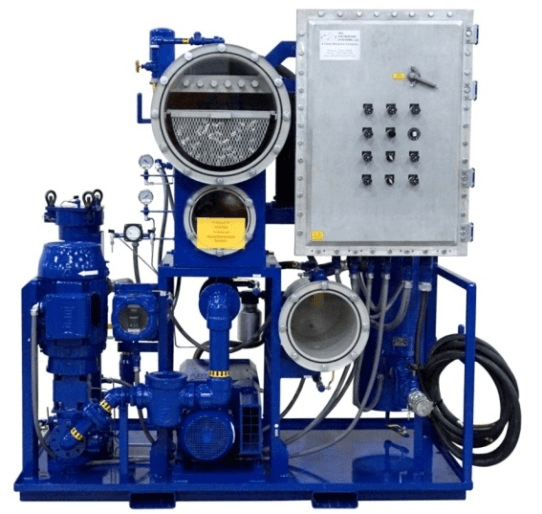

To eliminate the need for continuous oil sweetening, BioKem deployed an 80 LPM Vacuum Dehydration Oil Purification System (VDOPS) in a kidney-loop configuration. This system was:

-

Operated while the compressor was online

-

Installed in a zone-classified area

-

Connected to a flare system for safe gas discharge via vacuum distillation

This continuous re-circulation approach effectively removed entrained gases from the oil without interrupting operations.

Results

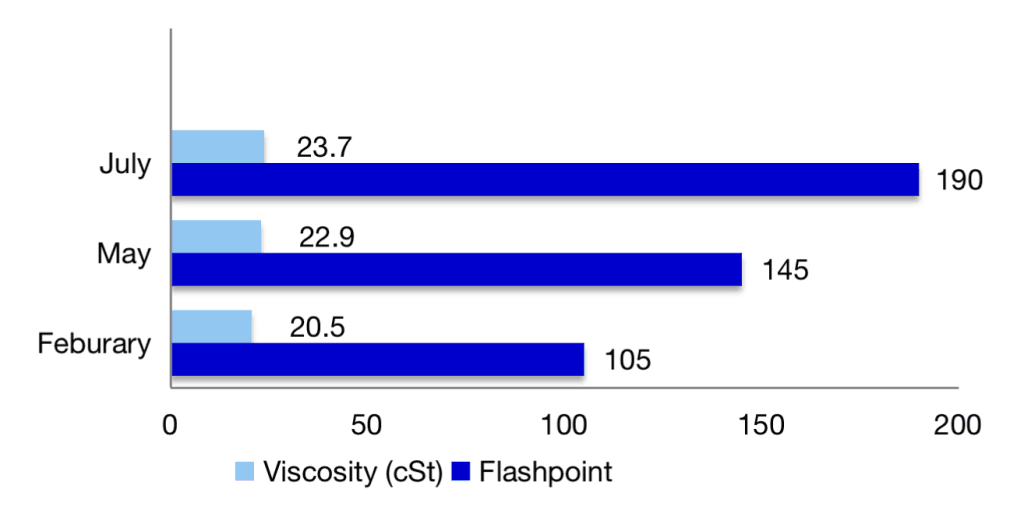

The impact of the VDOPS solution was clearly measurable:

Between February and July 2015, the condition of the compressor oil improved significantly. On February 5, the oil’s flashpoint was just 105°C with a viscosity of 20.5 cSt. By May 4, the flashpoint had increased to 145°C and the viscosity to 22.9 cSt. Continued purification led to even better results by July 7, when the flashpoint reached 190°C and viscosity improved to 23.7 cSt, demonstrating a substantial recovery in oil quality.

This steady improvement in oil condition not only reduced operational risk but also eliminated the need for costly oil sweetening, resulting in significant long-term savings.

This steady improvement in oil condition not only reduced operational risk but also eliminated the need for costly oil sweetening, resulting in significant long-term savings.

Return on Investment

Thanks to the successful implementation:

-

The plant no longer needed to sweeten the oil, eliminating $800,000 in annual oil costs

-

A new, permanent VDOPS unit was purchased and installed

-

The plant achieved an ROI in under two months, with minimal ongoing consumable costs

Conclusion

BioKem’s VDOPS solution provided a cost-effective, safe, and efficient way to eliminate entrained gas contamination in the gas compressor’s lube oil system—without operational disruption.

If your facility faces similar contamination or maintenance challenges, contact BioKem Oil Services to learn how we can help extend your equipment’s life while saving costs.

Case Study – Solar Centaur Package Upgrade

BioKem’s hot oil flush lube oil system service restored SOLAR CENTAUR performance and exceeded OEM cleanliness standards.

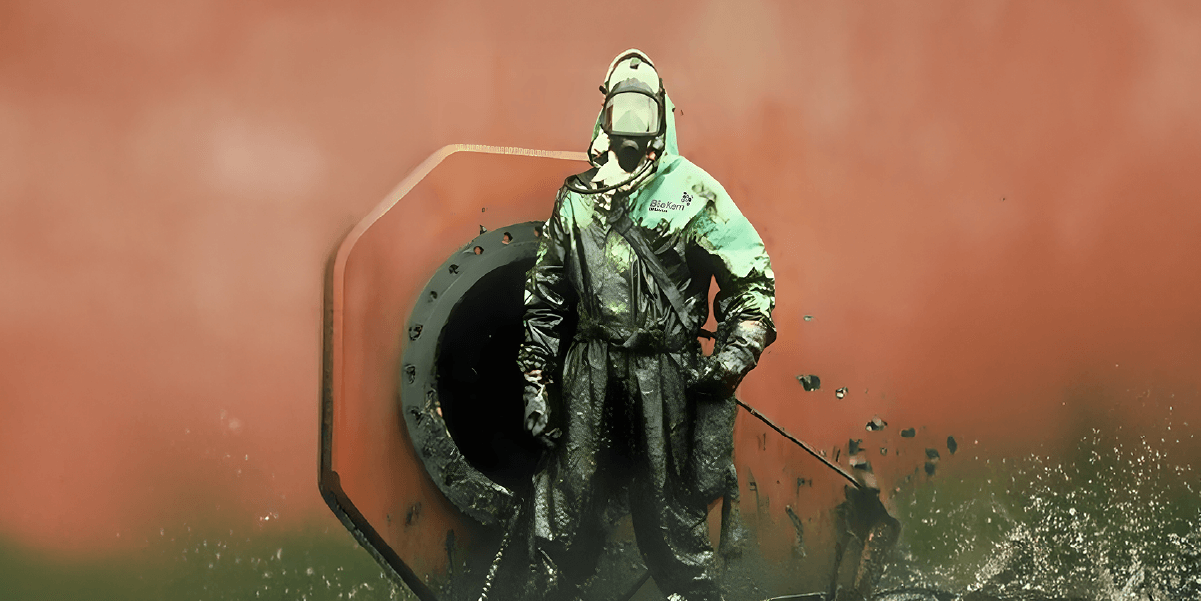

Confined Space Tank Cleaning

BioKem delivers certified confined space tank cleaning for oil, fuel & hydraulic systems – safe, efficient, and designed to prevent failure.

Should You Change to Synthetic Oils? Part II: Synthetic Might Not Be Right For You

Explore key considerations for synthetic oils, including seal compatibility, cost, and efficiency to help decide if they’re right for your application.

Should You Change to Synthetic Oils? Part I: The Advantages of Synthetic Oils

Learn the advantages of synthetic oils, including better efficiency, thermal stability, and resistance to degradation over mineral oils.

Sorting Out Your Lube Room – Keys to Best Practice Lubrication Storage

Learn best practice lubrication storage to optimize your lube room and enhance equipment performance for greater efficiency.

Condition Monitoring for Rotating Equipment

Learn how condition monitoring for rotating equipment prevents failures like abrasion, corrosion, fatigue, and inadequate lubrication.

Can You Extend the Life of Your Rotational Equipment?

Extend the life of your rotational equipment with clean lubricating oil. Learn how proper oil filtration increases equipment longevity.

Oil Filtration Methods: Key Techniques for Cleaner Oil

Discover effective oil filtration methods like barrier filters, vacuum dehydration, and centrifuges to ensure cleaner, longer-lasting oil.

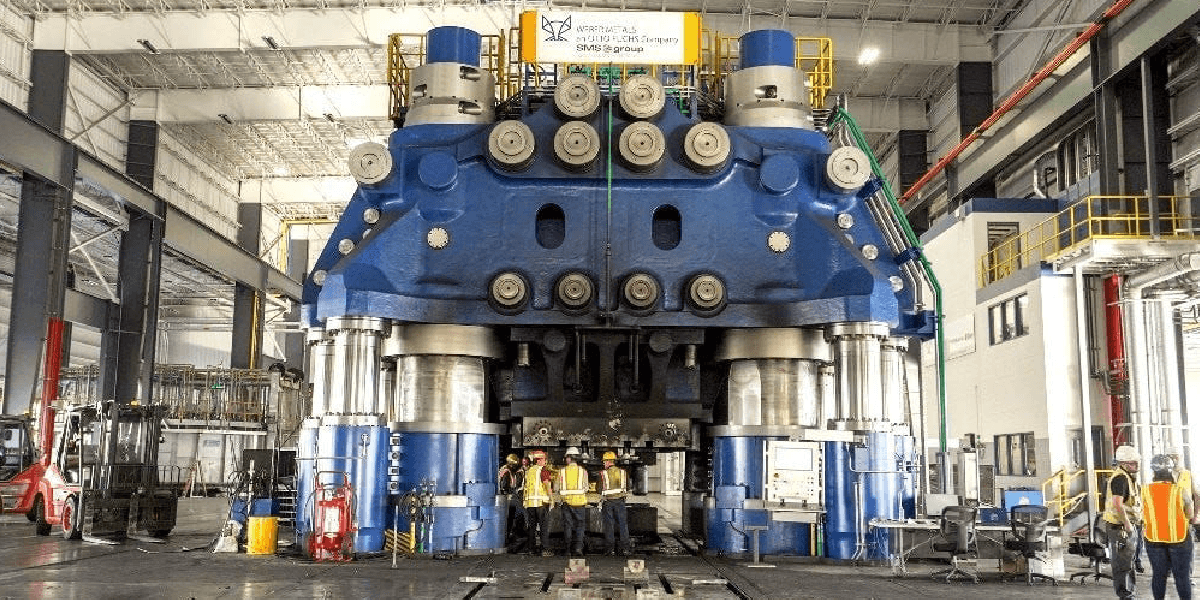

Case Study: Lubrication Oil Optimisation in an Aluminium Smelter

A leading Australian aluminium smelter achieved remarkable results through lubrication oil optimisation. Learn how they improved efficiency, extended asset life, and reduced maintenance costs.

The Objectives

After expanding and upgrading their systems with new cranes and gearboxes, the aluminium smelter aimed to:

- Maximise return on investment.

- Extend the lifecycle of assets.

- Minimise unscheduled downtime.

The Problems

The smelter faced several challenges:

- High Contamination Levels: Dirty environments led to frequent lubricant contamination, causing premature wear.

- Moisture Ingress: The humid atmosphere caused moisture-related issues, affecting lubrication performance.

- Short Service Cycles: Temperature fluctuations shortened oil service cycles, increasing costs.

- Unscheduled Downtime: Frequent downtime disrupted production and escalated maintenance costs.

The Challenges

The smelter needed to reduce downtime and enhance asset reliability while improving the efficiency of their lubrication system. Their goals included:

- Reducing contaminant levels in the oil.

- Extending the intervals between lubricant replacements.

- Upgrading lubricant quality without increasing overall costs.

The Solutions

The management formed a dedicated Condition Monitoring team to conduct a study and audit aimed at enhancing asset reliability.

Through comprehensive lube oil sample analysis, they identified the specific contaminants affecting the lubricants, traced their origins, analyzed how they entered the system, and evaluated their impact on components and wear rates.

The first step was to install breather filters on all lube oil compartments to prevent airborne contaminants from entering and to keep the oil cleaner. A critical part of this solution included establishing a robust maintenance program to ensure regular inspection, maintenance, and repair of the breather filters.

Next, they enhanced the fixed conditioning filtration system operating in a kidney loop setup. Vacuum dehydrators equipped with β1000 filtration using 5 or 10 μm filters were introduced to dramatically improve lube tank cleanliness and remove moisture. These upgrades reduced the ISO 4406 cleanliness code from new oil levels of 21/18/17 (NAS Class 10) to 16/14/12 (NAS Class 5) for compressors, and further to 15/13/11 (NAS Class 4) for hydraulic systems. As a result, the asset life cycle increased by 2.5 times, extending hydraulic oil change intervals to 7 years.

With an extended lubricant life cycle, the plant could justify upgrading to fully synthetic lubricants. This step further enhanced both asset and lubricant life cycles, but it underscored the importance of maintaining oil cleanliness and managing moisture effectively to sustain these gains.

Purification Tasks

The condition monitoring team used portable equipment to clean gearboxes, compressors, and hydraulic systems. Regular oil analysis programs confirmed ISO 4406 cleanliness targets and enabled early detection of wear or contamination.

Summary

By adopting lubrication oil optimisation strategies, this aluminium smelter achieved remarkable results by improving lubrication practices:

- Increased asset life cycle by 2.5 times

- Reduced downtime significantly

- Maximized return on investment

Want similar results? Contact us today to discuss your plant’s needs!

Moisture Damage in Compressors: Causes, Effects, and Solutions

Discover how moisture damage in compressors leads to varnish, corrosion, and sludge. Learn effective solutions to protect your equipment.

Do You Need to Take a Breather?

A lube oil tank breather protects your system from airborne contaminants, ensuring cleaner oil and better machinery performance.

New Oil is not Clean Oil

Ensure new oil cleanliness to protect your machinery from damage caused by contaminants in lubricating oil. Prevention is key.

Hot Oil Flushing (HOF)

Hot Oil Flushing removes contaminants, extending lubrication system life and reducing long-term maintenance costs.

Moisture could be your No. 1 Oil Lubrication Problem

If moisture is >300ppm, BAD things are happening in Your lube system.

If you worry about moisture levels in lubrication oil, your concerns are valid. Water contamination, even in small amounts, harms your plant and machinery. Moisture shortens both the machinery’s service life and the lubrication oil’s effectiveness.

Left Unchecked, Moisture Will Affect Your System.

The Dangers of Unchecked Moisture

Catastrophic Failure

Compressors handling ‘sour’ natural gas with high hydrogen sulfide levels face serious issues when moisture is present. The interaction between oil and moisture can cause sulfide stress cracking, a type of hydrogen embrittlement. In extreme cases, this may split compressor casings.

Hydrogen embrittlement also affects other equipment. Electrolysis or corrosion releases hydrogen atoms from water molecules, creating a damaging cycle.

Corrosion

Rust impairs bearing surfaces and prevents the formation of the critical elastohydrodynamic (EHD) film needed for effective lubrication.

Impaired Film Strength

Similar to corrosion, the oil is denied the opportunity to lubricate and separate the surfaces. This occurs when dissolved water affects the viscosity of the oil and allows the load zone to force the lubricant aside and ‘bump’.

Did You Know?

Water in the bearing load zone can create superheated steam, leading to mini-explosions within the oil. This phenomenon damages the oil and can harden, fatigue, or crack bearing surfaces.

Foaming

Water, especially chemically treated water, hinders the lube oil’s ability to dissipate foam. Excessive foaming causes sluggish hydraulic control systems and can lead to cavitation in pumps and bearings.

Lube Oil Additive Depletion

Additives are designed to be a sacrificial product. They are consumed as the additive pack anti-oxidant neutralises unwanted chemical contaminants. However, if additives such as demulsifiers (which help shed water) are exposed to large amounts of water contamination, the demulsifiers can be stripped from the oil very quickly leaving the oil at risk.

Other additives like Extreme Pressure (EP) and Anti-wear (AW) can be hydrolyzed (broken down into acids) by water and deny your Equipment the protection those additives are designed for. If left unchecked the by-product is sludge and varnish.

Sludge Formation

Water’s polar nature attracts contaminants, leading to sludge formation. Sludge can overwhelm strainers and filtration systems, restricting oil flow.

Microbial Contamination

Moisture promotes microbial growth in lubrication oil and diesel. This biomass can plug lube circuits and filtration systems. Microbial contamination poses corrosive effects and health risks.

Dry Oil Equals Extended Life of Oil & Machinery

A trial of machines by the BHRA compared equipment life to moisture contamination. They found the correlation between dry oil and oil with high moisture content. Oil with a moisture level of 5,000 ppm was dehydrated and trialled to measure equipment life. The results show that equipment with oil drier than 100ppm has three times the life of a machine with oil of 450ppm moisture.

Resolving the Problem of Moisture

Many solutions exist to mitigate moisture and particulate contamination. BioKem offers various units, including vacuum dehydrator VDOPS units. These units effectively remove dissolved, free, and emulsified water and particulates from different oil types. They feature microglass filtration media that can remove particles as small as 2 μm.

If you need advice on specifying or sizing a suitable unit for your plant, feel free to reach out.

Conclusion

Keeping lube oil moisture levels below 300 ppm is crucial for increasing equipment life and prolonging oil effectiveness. Proactive moisture management leads to significant cost savings and improved operational efficiency.

If you would like further information on this article or others, please feel free to contact us.

Reference

- Sulphide Stress Cracking – http://en.wikipedia.org/wiki/Sulfide_stress_cracking

-

Vacuum Dehydration Oil Purification Systems (VDOPS) – https://www.oilfiltrationsystems.com/vacuum-dehydration-oil-purification-systems-vdops

The Hidden Dangers of Topping Up Your Lube Oil

Stop! Don’t Blend Your Lube Oils Until You Have Read This

You may not realise it, but older machines often have blended oils. If your machine is several years old, its oil likely mixes different oil groups. Many Group I oils have been phased out by oil companies. They were replaced with improved Group II formulations that often carry similar labels. Topping up lube oil with these formulations can lead to unintentional blending. This can harm your equipment, so it’s important to understand these issues.

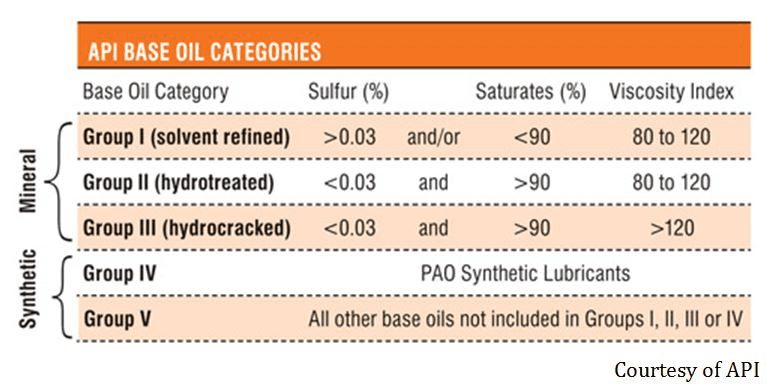

Understanding Oil Groups: What’s the Difference?

Mineral oil is a natural resource derived from the earth. It forms over millennia from decomposed organic material. Crude oil is refined to create a base stock. This base stock is then blended with additives to develop lubricants tailored to specific applications.

The degree of refining significantly impacts the oil’s properties. More intensive refining usually results in improved performance. Mineral oils are categorized into Group I, II, and III, with Group I being the least refined.

In contrast, synthetic oils are man-made. They fall into Group IV and Group V. Synthetic oils are generally more expensive than mineral oils but offer a significantly longer service life.

The development of synthetic lubricants arose from the need for better performance. This was especially true in environments where crude oil was scarce, such as wartime Germany. Aviation was one of the first industries to adopt synthetic oils. These oils outperform mineral oils during cold starts and in cold climates.

Synthetic oils also have a higher Viscosity Index. This means they maintain better viscosity stability across varying temperatures.

Group IV synthetic oils are produced from PAO’s (polyalphaolefins). Group V oils consist of various synthetic molecules, including polyesters, phosphate esters, di-esters, and alkylated benzenes. Each type offers specialized properties for different industrial applications.

Comparing Oil Groups: What’s Inside?

Another way to compare oil refinements is to visualize it as a fluid with suspended balls of varying sizes. The lower the Group level of the oil, the greater the variety of ball sizes and shapes. These represent different types of molecules.

Group I oils contain millions of differing atomic compounds. As oil is refined, it becomes more uniform. This results in ‘balls’ of similar size. In contrast, synthetic oils consist of only one size of ball.

Group I Oil – millions of compounds |

Group IV & V – Synthetic Oil |

Oil Clarity and Sulphur Levels

The brown color in oil primarily indicates its sulphur content. As you move up the Group levels, the sulphur content decreases, resulting in clearer oil—sometimes as clear as water, like baby oil.

Group III oil may be referred to as ‘synthetic,’ but it is not truly synthetic; it simply behaves more like synthetic oil.

Oil Blending: Availability and Consequences

With the phase-out of Group I oils due to technological advancements, Group II oils have become more affordable and widely available. However, blending Group I with Group II oils can lead to contamination and oxidation, reducing performance and causing varnish buildup.

Group I oil is now unavailable in lighter grades. As a result, industries often top up Group I lube compartments with Group II oils, hoping for compatibility. In-service Group I oil may contain waste by-products of oxidation. This occurs due to depleted antioxidants, which are a primary cause of varnish. It may also have other contaminants, like wear metals and environmental pollutants.

Adding ‘make-up’ Group II oils introduces new antioxidants. However, these can be quickly depleted by the existing Group I oil. This leads to further varnish potential as waste by-products accumulate.

Before adding Group II oil to your Group I oil, consult your supplier for compatibility. Ensure that your Group I oil is clean and free of contaminants. Check that it has sufficient antioxidants or remaining useful life. Confirm whether mixing is truly necessary. It’s also wise to conduct an RPVOT Oxidation test with your lab.

Warning: If your Group I oil is beyond recovery (oxidized), do not try to rejuvenate it by adding Group II oil. Instead, drain and flush your system. Then, add a fresh charge of Group II oil.

Rotating pressure vessel oxidation test (RPVOT) – ASTM D2272, formerly called the rotating bomb oxidation test (RBOT)

Rotating pressure vessel oxidation test (RPVOT) – ASTM D2272, formerly called the rotating bomb oxidation test (RBOT)

The Twisty Turny Bit

Blending oils can mislead laboratory results. This may make it seem that antioxidant levels are acceptable. In reality, the new Group II oil skews the readings.

Keep this in mind and look for other indicators, such as visual varnishing and staining. If you’re uncertain, inspect the oil cooler elements on the off-duty unit. Staining indicates that the oil has broken down and is shedding its additive package.

You may need to remove the blended oil. Treat the varnish, flush the system, and replenish with new polished Group II oil.

Tip: Ensure your new oil is polished (filtered) before use. It may not meet equipment OEM cleanliness (ISO 4406) standards when supplied by the oil reseller!

ISO 20/18/16 NAS 10 – sample from ‘new’ oil delivered in a tote |

ISO 15/12/10 NAS 4 – Polished with 2μm microglass media |

Pros and Cons of Oil Groups

Group I Oils:

- Pros:

- Historically cheap and readily available.

- Greater tolerance to particle and water contamination.

- Cons:

- Degraded Group I oil can change its molecular structure and become carcinogenic.

Group II Oils:

- Pros:

- Readily available and affordable.

- Can withstand higher operating temperatures.

- Increased service life, better wear protection, and improved lubricity.

- Cons:

- Lower threshold for varnish-causing contaminants.

Group III Oils:

- If you manage clean oil, moisture, and particulates effectively on your site, Group III oils can provide superior wear protection and an improved Viscosity Index for your machines.

Managing Oil Cleanliness: Best Practices

Many solutions are available today to reduce moisture and particulate contamination. BioKem offers a range of units for this purpose. For optimal results, consider a VDOPS vacuum dehydrator.

These units effectively remove dissolved, free, and emulsified water. They also eliminate entrained gas and particulates from heavy gear oils to very light oils of any Group. VDOPS units are regarded as the gold standard in the filtration industry. They feature class-leading microglass filtration media that removes particles as small as 2μm.

If you need advice on specifying or sizing a suitable unit for your plant, please let us know.

Conclusion: Avoid Blending—Drain, Flush, and Refill

Avoiding ad hoc mixing or blending of old and new oils will benefit your lube circuits and rotational equipment. In critical, close-tolerance rotating equipment, the risks of blending are simply not worth it.

If possible, Don’t blend – Drain, Flush, Polish and Refill!

If you would like further information on this article or others, please feel free to contact us.

Special Report: How to Read Lube Oil Lab Reports for Maximum Equipment Life

Maximize Equipment Life: Understanding Your Lube Lab Reports

Your lubricant lab reports serve as an early warning system, helping you identify issues before they escalate into costly repairs or downtime. By regularly analyzing and testing your lube oil, you can extend the life of your equipment and ensure optimal performance. Here’s how to interpret key indicators from your lab report to take proactive action.

5 Key Indicators to Check on Your Lube Oil Lab Reports

Lab reports provide critical insights into the current condition of your lubricant and how it’s evolving over time. They aren’t just about oil degradation; they offer a snapshot of your oil’s quality and provide actionable recommendations to prevent the lubricant from falling below acceptable standards.

Here are the top five things to look for when reviewing your lab report:

1. Is it the Right Report?

The first thing to check sounds obvious, but it is very important. You should check that the report is your report, and that it is for the specific machine you are assessing. This is particularly important if you are responsible for the operation of multiple machines, or multiple sites.

The information that is typically included on a Lab Report includes:

- Unit ID

- Unit make

- Unit model

- Unit serial number

- Site or location of the unit

- Compartment name, ID, make, model, serial number

- Capacity

- Lubricant manufacturer

- Lubricant type

- Lubricant grade

The report will also give details of when the sample was taken, as well as when it was received in the lab and reported on. All of this information will help you confirm that the report is the one that you should be assessing.

Tip – If the sample details seem incorrect, labeling issues may have occurred during the testing process.

2. Review Physical Properties of the Lubricant

The next step is to examine the data from the physical tests of the most recent sample. Water levels, or moisture content, are likely to be a significant concern. These levels are usually reported in parts per million (PPM) or as a percentage of saturation. In the report, you should look for how close the moisture levels are to the saturation point. Since oils vary widely, there is no universal benchmark threshold; therefore, consult your OEM recommendations for acceptable oil and machine moisture levels.

Other physical properties to check include:

- ISO 4406 Rating: Indicates particle contamination levels.

- TAN (Total Acid Number): Tracks additive depletion.

- TBN (Total Base Number): Monitors combustion environment impacts.

- Viscosity: Consistency is crucial.

- PQ Index: Measures ferrous metal content.

- Color: A significant color change may indicate oil contamination or blending.

- Oxidation: Tracks oil degradation over time.

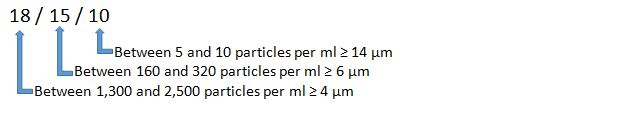

ISO 4406 ratings provide a standard measurement of particle contamination in lubricants, expressed as three numbers (e.g., 18/15/10). Each number represents the quantity of particles in three different size ranges, with the first number indicating the smallest particles and the last number the largest.

For instance, in the rating 18/15/10:

- There are between 1,300 and 2,500 particles that are ≥ 4µm.

- There are between 160 and 320 particles that are ≥ 6µm.

- There are between five and ten particles that are ≥ 14µm.

Here is the chart with the ISO 4406 range codes which you can use to reference your result. The first number is a range code (the number you will see on your report), and the second is a range in parts per millilitre:

- 24 – Between 80,000 and 160,000 particles

- 23 – Between 40,000 and 80,000 particles

- 22 – Between 20,000 and 40,000 particles

- 21 – Between 10,000 and 20,000 particles

- 20 – Between 5,000 and 10,000 particles

- 19 – Between 2,500 and 5,000 particles

- 18 – Between 1,300 and 2,500 particles

- 17 – Between 640 and 1,300 particles

- 16 – Between 320 and 640 particles

- 15 – Between 160 and 320 particles

- 14 – Between 80 and 160 particles

- 13 – Between 40 and 80 particles

- 12 – Between 20 and 40 particles

- 11 – Between 10 and 20 particles

- 10 – Between 5 and 10 particles

- 9 – Between 2.5 and 5 particles

- 8 – Between 1.3 and 2.5 particles

- 7 – Between 0.64 and 1.3 particles

- 6 – Between 0.32 and 0.64 particles

Warning – As soon as you see high moisture levels, take action. This will destroy the additives and drag your lube oil out of spec with disastrous results.

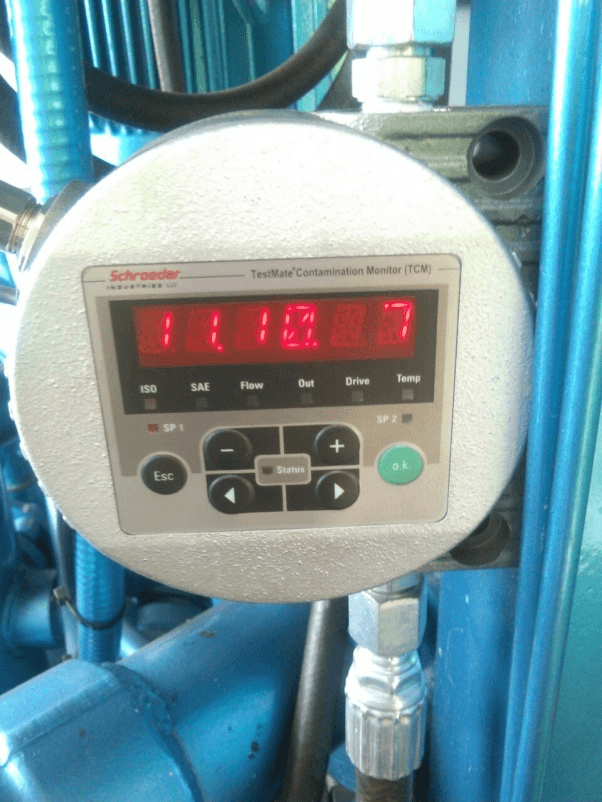

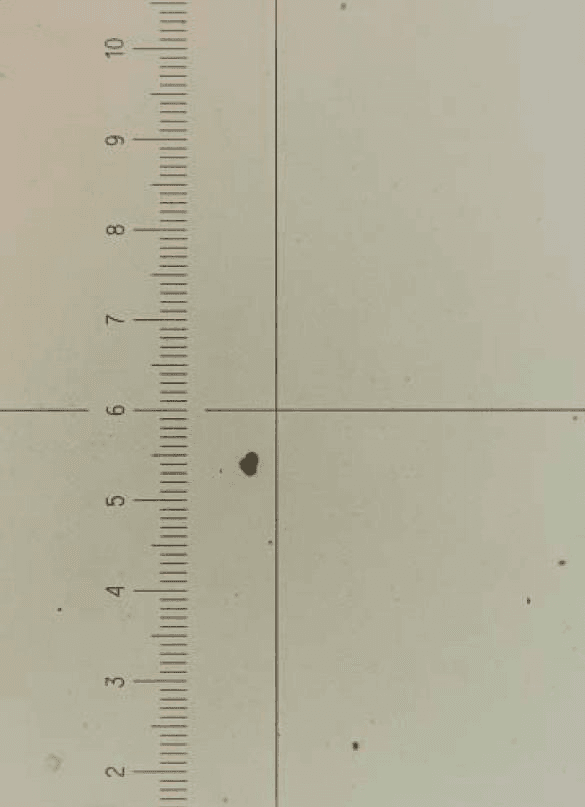

Digital Particle counter on a VDOPS reading 11/10/7. Very clean oil.

3. Metals and Contaminants Analysis

Elemental spectroscopy identifies the presence of wear metals and contaminants, typically measured in PPM (parts per million). The report will list elements like iron, chromium, aluminum, and lead, which can indicate wear debris from your machine’s components. High levels of these metals may suggest mechanical issues that need addressing.

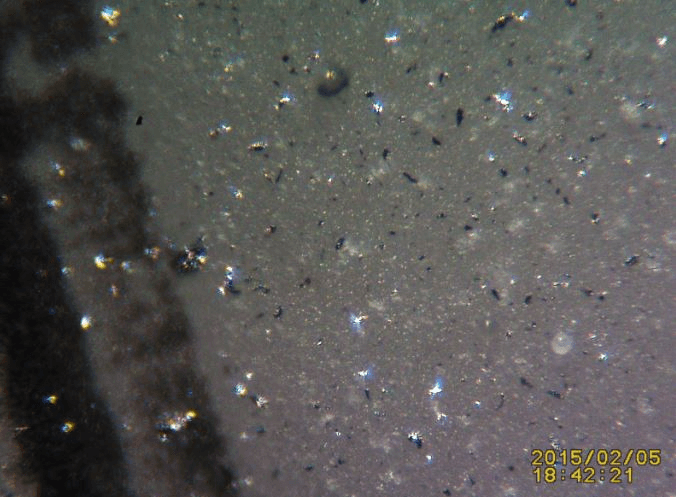

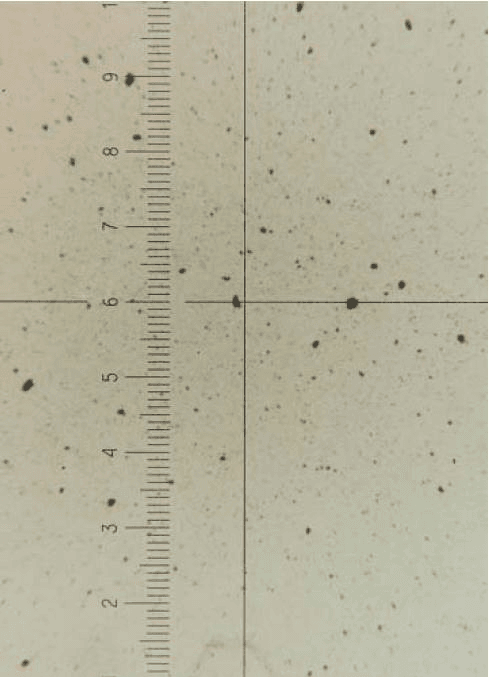

BioKem Oil Services Patch Test at 100x Mag showing severe chromium wear debris

4. Compare Trends Over Time

Analysing trends from past samples is one of the most valuable aspects of your lab report. Look for gradual increases in contaminants or changes in lubricant quality. This trend analysis helps you predict when restoration or maintenance work might be necessary, ensuring your equipment operates smoothly and reducing downtime.

5. Read the Summary and Recommendations

Lab technicians often provide a summary of the report, confirming your own interpretation of the data. Pay close attention to any recommended actions, such as scheduling the next test or maintenance tasks. Taking these recommendations seriously can help catch potential problems early.

Conclusion: Ensure Maximum Equipment Efficiency

Regular review of your lubricant lab reports is critical to maintaining your equipment’s performance. Checking for the right indicators and acting on trends can help extend the life of your machinery and prevent costly breakdowns. Remember to verify that particle counts, moisture levels, and contaminant levels remain within acceptable limits.

Cost-Benefit Analysis: Preventative maintenance through regular oil testing and analysis is far more cost-effective than addressing failures caused by poor lubrication.

If you would like further information on this article or others, please feel free to contact us.

How do you know if you have varnish in your lube system?

Prevent machine failures from lubricant breakdown. Learn warning signs, varnish detection, and solutions to avoid costly downtime.