Introduction

BioKem was engaged to perform a pre-commissioning hot oil flush of two upgraded lube oil cooler packages and their interconnecting spool systems. This was part of a critical upgrade on a SOLAR CENTAUR gas compressor package.

The Problem

A glycol leak in the existing cooler packages contaminated the lube oil system of an operational gas compressor. Initially minor, the leak went unnoticed until it had already caused significant internal damage – highlighting the need for immediate intervention and contamination removal.

Project Challenges

To meet OEM specifications, the upgraded cooler packages needed to be completely free from contaminants before commissioning. These specifications included:

-

Flushing flow rate: Minimum 848 LPM

-

Flushing temperature: 71°C

-

Cleanliness code: ISO 4406 16/14/12 or better

-

Moisture content: <200 ppm

Additionally, BioKem was required to meet stringent on-site safety protocols and work within a tight project schedule. Due to time constraints, the job was executed in two carefully planned stages.

BioKem’s Solution

The upgraded compressors were fitted with Fin Fan (air-to-oil) cooler packages and new pipework. BioKem then carried out a hot oil flush using a Vacuum Dehydration Oil Purification System (VDOPS 190), along with flushing pumps and reverse flow manifolds.

Real-time monitoring tools, including a digital ISO 4406 particle counter and moisture analyzer, were used throughout the process to ensure all OEM targets were consistently met. For environmental compliance, all operations were conducted in a bunded container.

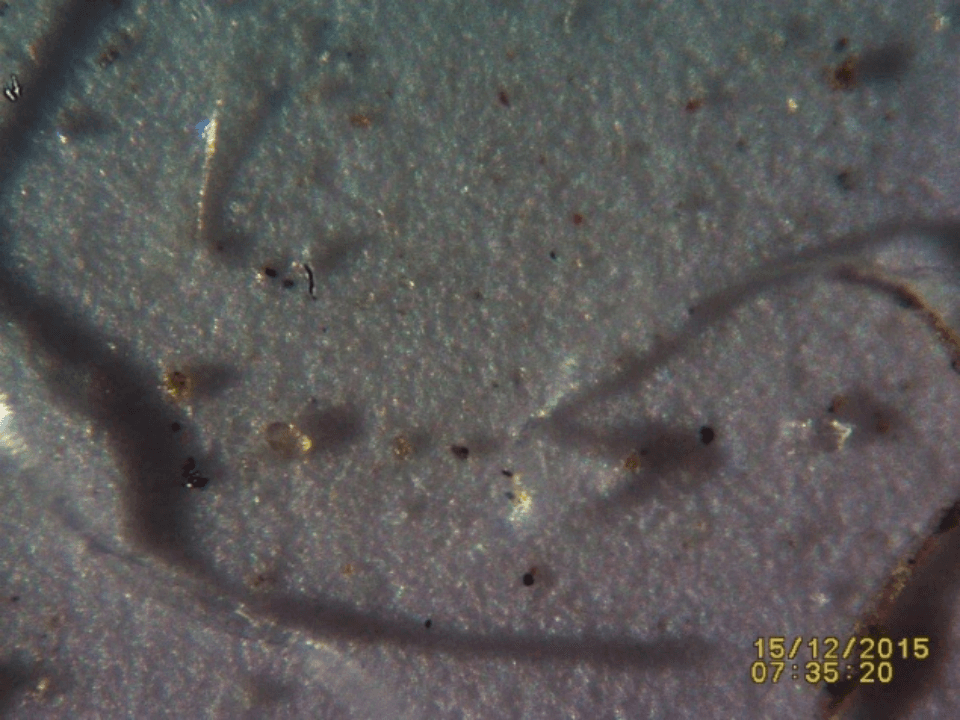

Patch Testing

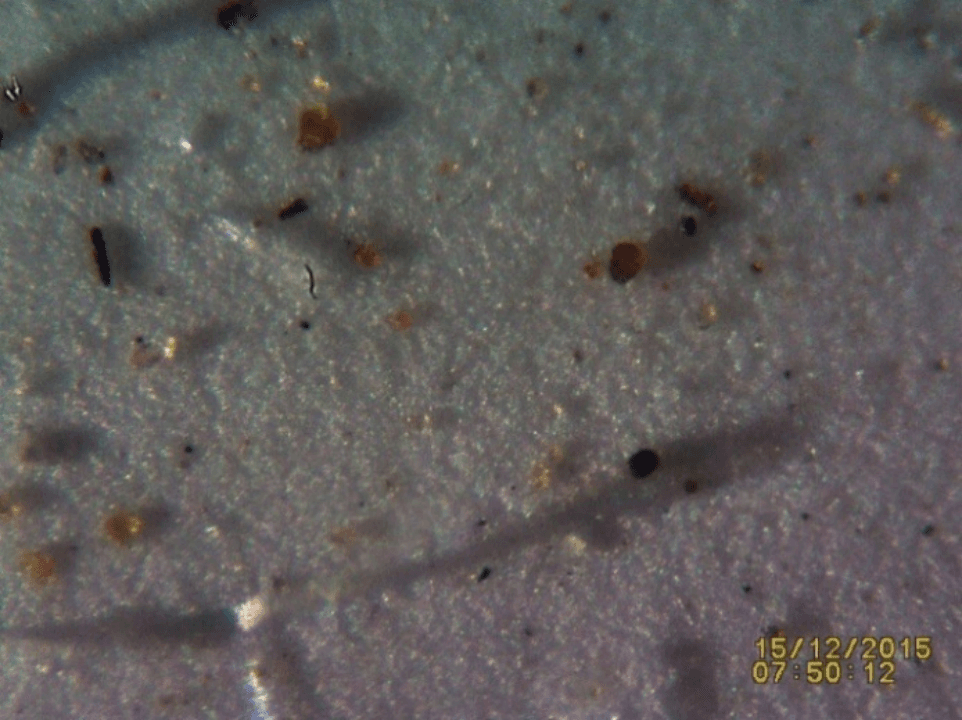

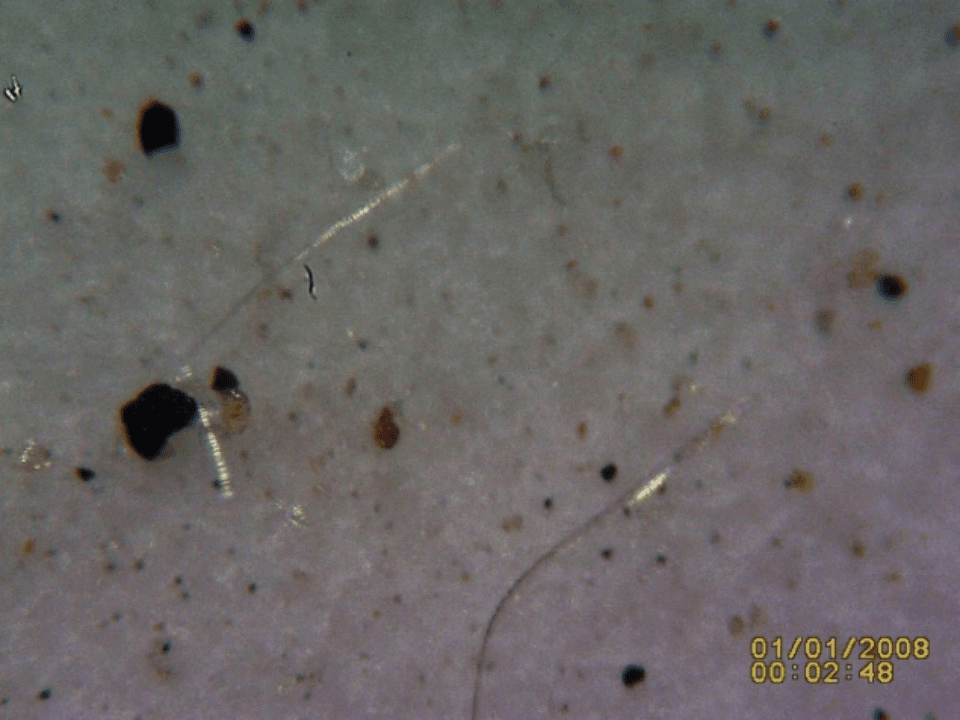

BioKem obtained samples from both compressors prior to the commencement of operations and conducted patch testing on each. A high density of contaminants, varying in size, was identified upon close examination. These included silica and carbon particles, steel strands, cellulose fibres, and large fragments of varnish – see Figures 1 and 2 (taken using a 100x magnification microscope). Additional photos can be found in Appendix A.

Figure 1: In-service oil in Compressor (Varnish). Figure 1: In-service oil in Compressor (Varnish). |

Figure 2: In-service oil in Compressor (Various Particulates) Figure 2: In-service oil in Compressor (Various Particulates) |

Samples were taken periodically, and patch testing was conducted to reaffirm ISO readings. Figures 3 and 4 below are from patch testing conducted on post-flushing samples. Additional photos can be found in Appendix B.

Figure 3: Post Flushing Oil Sample 1 Figure 3: Post Flushing Oil Sample 1 |

Figure 4: Post Flush Oil Sample 2 Figure 4: Post Flush Oil Sample 2 |

Purification Process

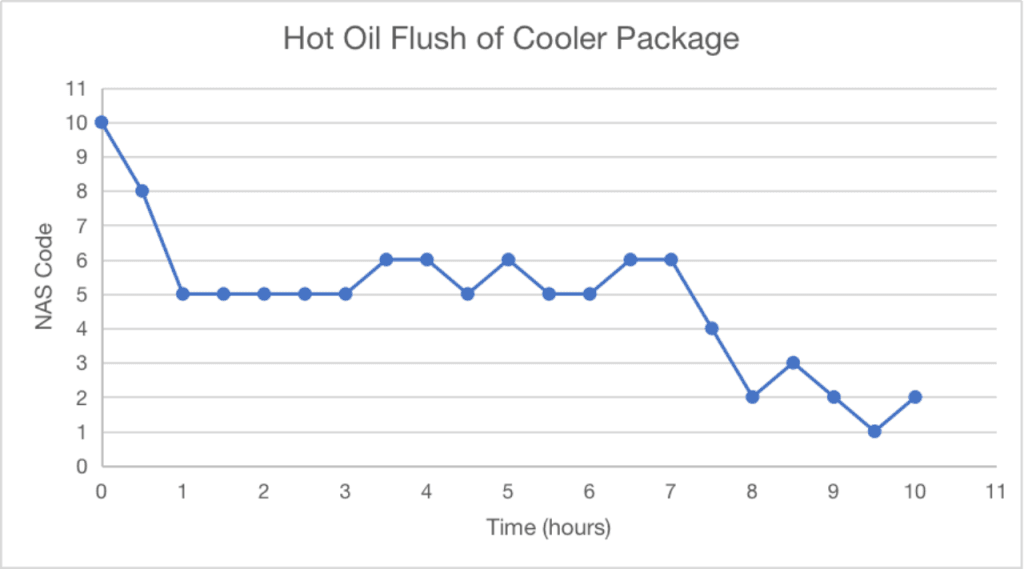

BioKem used the VDOPS 190 system, along with a flushing skid and reverse flow manifold, to flush the upgraded cooler package. The initial ISO 4406 particle count was 19/18/16 (NAS 10). Within one hour of flushing, the oil reached the OEM’s cleanliness specification of 16/14/12 (NAS 5).

Despite this, patch testing revealed that contamination remained in the system. Flushing and filtration continued for a total of 10 hours, eventually achieving an ISO particle count of 12/12/11 (NAS 2). At that point, patch testing confirmed that contaminants had been fully removed from the hot oil flush lube oil system.

The ISO particle count collected during the flushing process was converted into NAS Code equivalents and charted in Figure 5. The graph illustrates how oil quality stayed at the OEM’s NAS 5 standard for several hours before improving further to NAS 2/NAS 1 levels.

A full ISO 4406 to NAS Code conversion table is available in Appendix C.

Figure 5: NAS Code – Hot Oil Flush of Heat Exchanger Package

Summary

While the OEM’s oil cleanliness criterion was quickly achieved during each flush, further testing indicated that contaminants were still present in the lube oil system. To ensure complete system integrity, BioKem continued flushing and filtration until patch testing confirmed no visible contamination remained. As a result, the team achieved an oil cleanliness level several codes lower than the OEM’s requirements – dramatically increasing oil life and supporting long-term equipment reliability.

The use of real-time oil analysis instruments for both particulate and moisture levels allowed the job to be performed with precision – without the need for estimations. These digital readings were verified through laboratory patch testing, ensuring complete confidence in the results.

Key outcomes:

-

BioKem completed the hot oil flush lube oil system service within the quoted timeframe

-

The oil was cleaned beyond OEM standards

-

Asset downtime was avoided, and both oil and equipment life were extended

If you need a professional service to filter or hot oil flush your circuitry, spools, coolers, lube tanks, or manifolds, contact BioKem Oil Services today.

Appendix A: Patch Test of In-service Oil in Compressors at 100x Magnification

Figure 6: Varnish Fragment Figure 6: Varnish Fragment |

Figure 7: Various Contaminants Figure 7: Various Contaminants |

Figure 8: Various Contaminants Figure 8: Various Contaminants |

Figure 9: Various Contaminants Figure 9: Various Contaminants |

Appendix B: Patch Test of Post Flushing Oil in Compressor at 100x Magnification

Figure 11: Post Flushing Sample 1 Figure 11: Post Flushing Sample 1 |

Figure 12: Post Flush Sample 2 Figure 12: Post Flush Sample 2 |

Figure 13: Post Flush Sample 3 Figure 13: Post Flush Sample 3 |

Figure 14: Post Flush Sample 4 Figure 14: Post Flush Sample 4 |

Appendix C: ISO4406 / NAS Code Comparison Table

Figure 15_ISO4406 / NAS Code Comparison Table