Introduction: Reclaim Used Hydraulic Oil

Why throw away perfectly usable hydraulic oil just because it’s dirty? Many older hydraulic systems leak oil onto the plant floor or into pits, leading operators to dispose of the used oil and replace it with new. However, this used oil often only contains water and particulate contamination – issues that can be resolved without replacement.

Disposing of contaminated oil and purchasing new stock is expensive. There is a smarter solution: reclaim used hydraulic oil using a Vacuum Dehydration Oil Purification System (VDOPS) from BioKem Oil Services.

Showing dirty hydraulic oil as it is progressively cleaned, highlighting free water, emulsified oil, and clean/bright oil

Showing dirty hydraulic oil as it is progressively cleaned, highlighting free water, emulsified oil, and clean/bright oil

The Problem: Dirty Hydraulic Oil from Leaks

Older hydraulic equipment often develops leaks, which leads to oil loss and contamination. The used oil ends up being labelled “waste oil” and discarded – though it may still be chemically sound. Typically, it only contains water and particulates, making it a candidate for purification rather than disposal.

Avoid using “Waste Oil” to label the IBC/Drums to reduce contamination

Avoid using “Waste Oil” to label the IBC/Drums to reduce contamination

The Solution: Reclaim Used Hydraulic Oil with VDOPS

BioKem Oil Services offers an efficient and economical solution through its VDOPS system. If the oil is wet and dirty but otherwise intact, it can be purified in-house following a simple process:

-

Collect oil in a clean “dirty oil” tank (avoid the term “waste oil”).

-

Pump it into a batch tank with filtration to remove bulk particulates—or send it to BioKem’s depot.

-

Use VDOPS to remove water and fine particulates.

-

Transfer the reclaimed oil into a clean tank, ready for reuse.

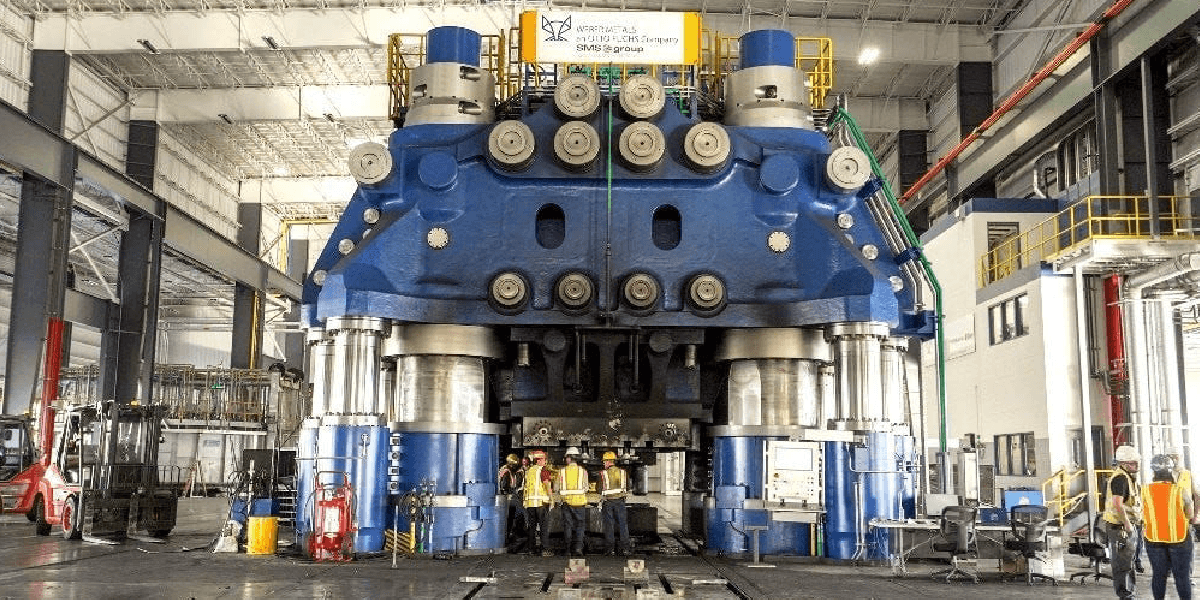

Vacuum dehydrator operating in our depot location

Vacuum dehydrator operating in our depot location

Results: Clean Oil That Exceeds New Oil Standards

The VDOPS process typically takes just 24–48 hours. Once complete, the oil meets or exceeds new cleanliness specs (ISO 16/14/11 and <100 ppm water content). This makes it suitable for reuse, saving costs on both disposal and new oil purchases.

Vacuum dehydrator – VDOPS80

Vacuum dehydrator – VDOPS80

Conclusion

If your facility spends money on disposing of used hydraulic oil and buying new, consider reclaiming it instead. BioKem’s expert team can visit your site, assess your system, and help implement a customised Oil Reclamation Program to reduce costs and support sustainable practices.

Contact BioKem Oil Services today to learn how you can reclaim used hydraulic oil and reduce operational costs.