Introduction

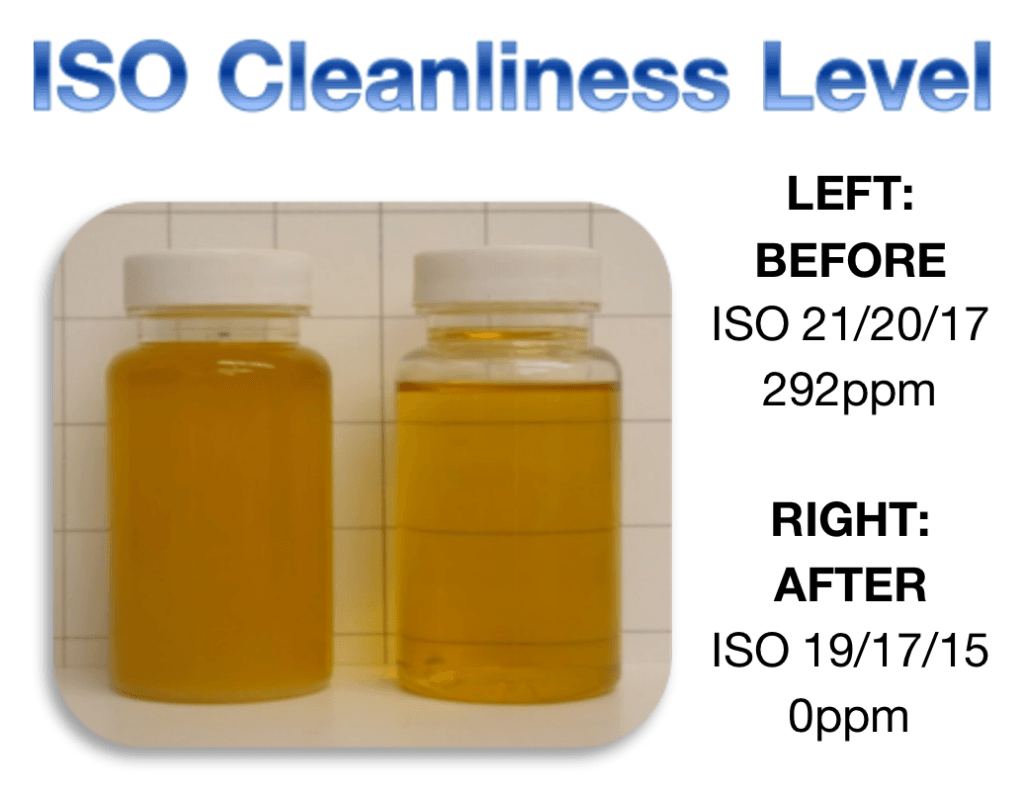

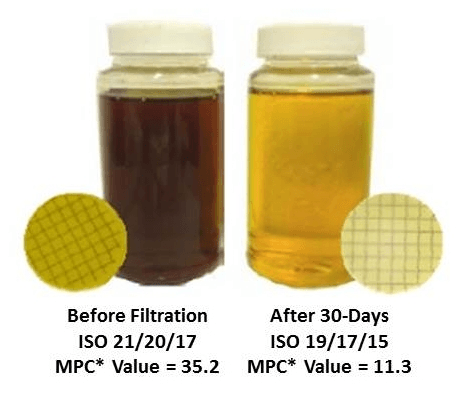

Gas compressor oil contamination poses a major risk to equipment performance and reliability. At a large industrial site, a CO₂ compressor’s 700L ISO VG 68 lube oil system showed excessive levels of varnish, water, and particulates. Oil analysis returned an MPC value of 35.2, water content at 292 ppm, and an ISO Cleanliness Code of 21/20/17 – well above OEM specifications. Immediate action was needed to avoid costly downtime and mechanical damage.

The Problem: Unchecked Gas Compressor Oil Contamination

Oil analysis revealed high contamination levels. The MPC reading was 35.2, with water content at 292 PPM. The ISO Cleanliness Code was 21/20/17, which exceeded the OEM’s cleanliness specifications. Without intervention, varnish would eventually plate out on metal surfaces, reducing compressor efficiency. The water and particulates could lead to premature failure of the rotating equipment.

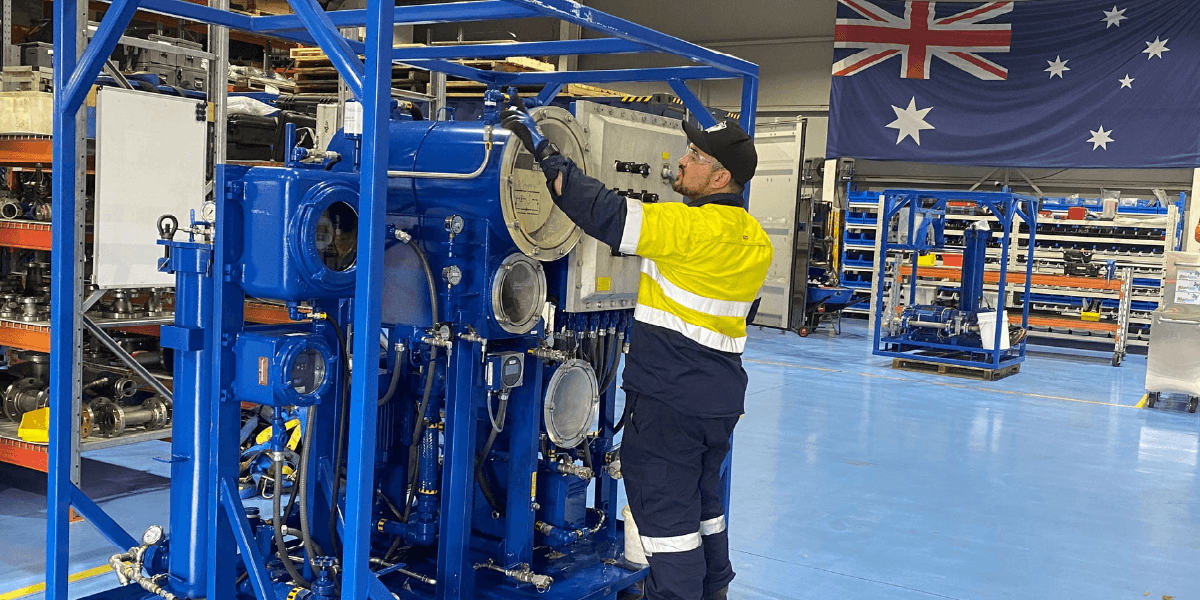

The Solution: In-Service Oil Purification for Gas Compressor Systems

To resolve the issue, BioKem implemented a 20lpm Vacuum Dehydration Oil Purification System (VDOPS). The VDOPS included a varnish removal housing with granular adsorbent media. The system was set up to recirculate the lube oil reservoir in a kidney-loop configuration, continuously removing contaminants while the compressor was running.

The Results: Purification Success and Improved Oil Quality

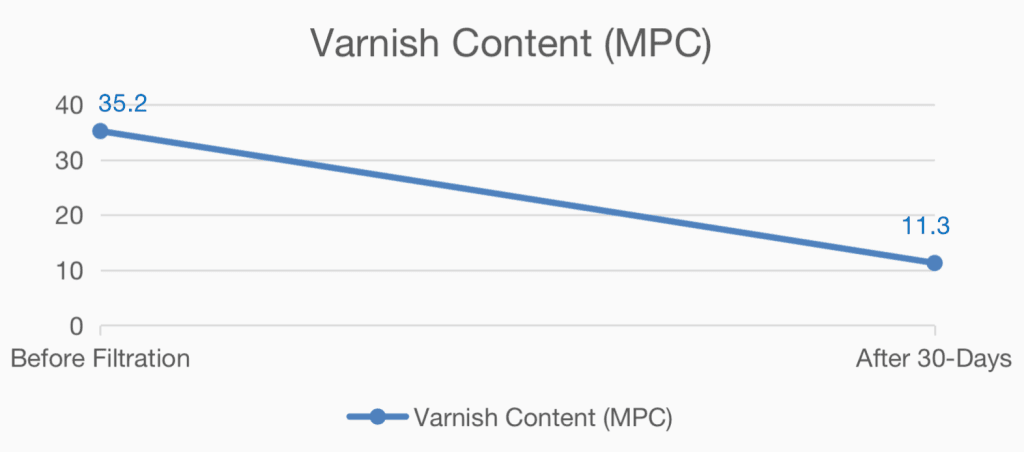

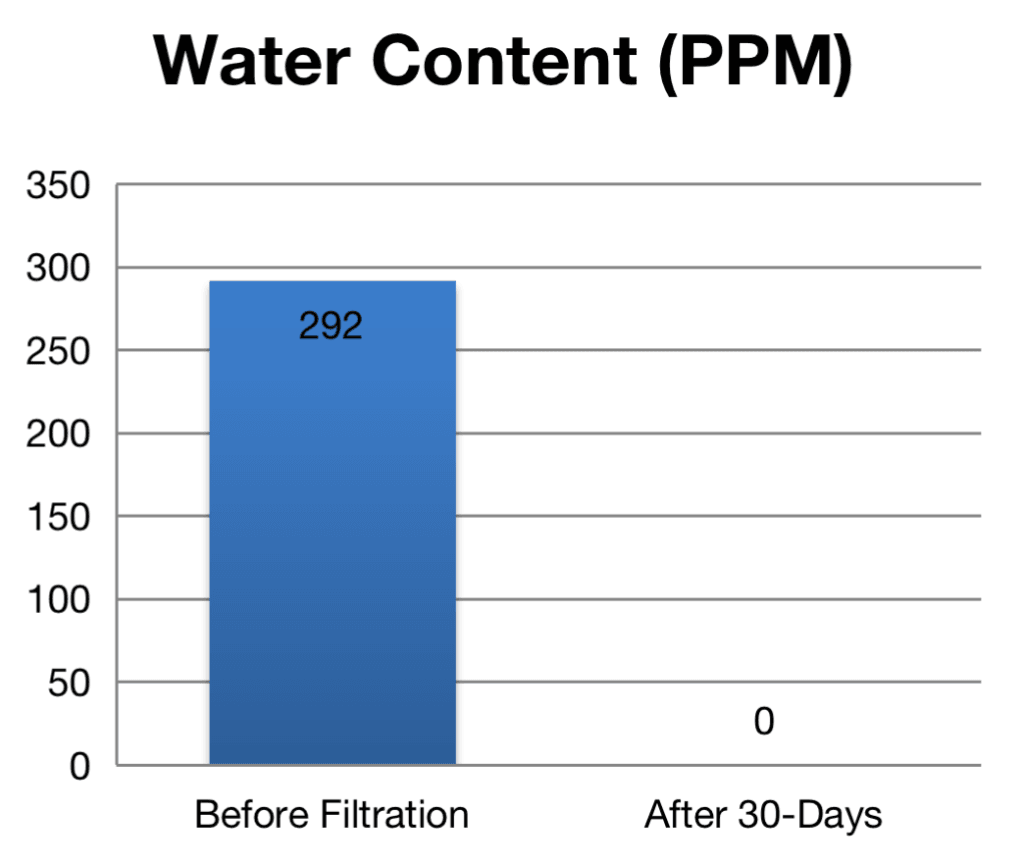

After 30 days of online purification, oil analysis confirmed a significant improvement:

-

MPC reduced from 35.2 to 11.3

-

Water content dropped from 292 ppm to <10 ppm

-

ISO Cleanliness improved from 21/20/17 to 19/17/15

These results demonstrated a successful recovery from gas compressor oil contamination, bringing the system back within OEM cleanliness standards.

These results demonstrated a successful recovery from gas compressor oil contamination, bringing the system back within OEM cleanliness standards.

Conclusion

By maintaining the lube oil at or below OEM cleanliness levels, operators ensure optimal compressor performance and reliability. This process helps reduce downtime and prevent costly repairs, increasing the overall lifespan of the equipment.

Is your compressor oil outside of spec? Contact BioKem Oil Services today for expert oil contamination solutions and advanced in-service purification tailored to your equipment.