Introduction

At a major petrochemical facility, a gas compressor’s lube oil system became contaminated with acetylene gas due to a leaking seal. The 3,000L system faced severe risks as light-end hydrocarbon gases – including H₂S, benzene, toluene, and acetylene – lowered the oil’s flashpoint and negatively impacted the viscosity of the ISO VG 32 compressor oil, making it ineffective as a lubricant.

The Problem

Shutting down the compressor to repair the leak would have resulted in major downtime and excessive cost. Instead, plant operators resorted to “sweetening” the oil—adding new oil through the fill port and draining the contaminated oil from the bottom. This ongoing process cost approximately:

-

$67,500 per month in new oil

-

$800,000 annually, excluding labour costs

Despite the effort, the entrained gas contamination in the lube oil system continued to compromise safety and performance.

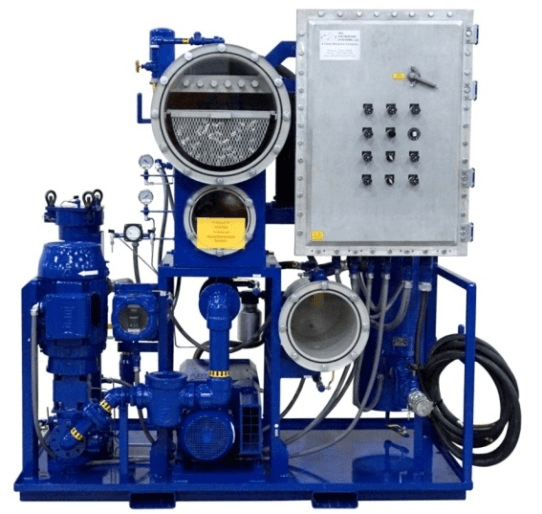

The BioKem Solution

To eliminate the need for continuous oil sweetening, BioKem deployed an 80 LPM Vacuum Dehydration Oil Purification System (VDOPS) in a kidney-loop configuration. This system was:

-

Operated while the compressor was online

-

Installed in a zone-classified area

-

Connected to a flare system for safe gas discharge via vacuum distillation

This continuous re-circulation approach effectively removed entrained gases from the oil without interrupting operations.

Results

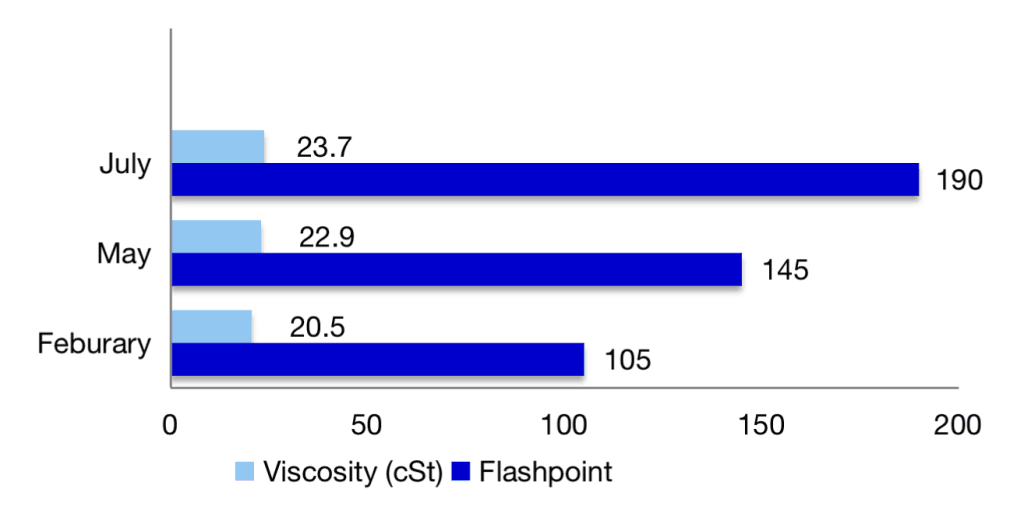

The impact of the VDOPS solution was clearly measurable:

Between February and July 2015, the condition of the compressor oil improved significantly. On February 5, the oil’s flashpoint was just 105°C with a viscosity of 20.5 cSt. By May 4, the flashpoint had increased to 145°C and the viscosity to 22.9 cSt. Continued purification led to even better results by July 7, when the flashpoint reached 190°C and viscosity improved to 23.7 cSt, demonstrating a substantial recovery in oil quality.

This steady improvement in oil condition not only reduced operational risk but also eliminated the need for costly oil sweetening, resulting in significant long-term savings.

This steady improvement in oil condition not only reduced operational risk but also eliminated the need for costly oil sweetening, resulting in significant long-term savings.

Return on Investment

Thanks to the successful implementation:

-

The plant no longer needed to sweeten the oil, eliminating $800,000 in annual oil costs

-

A new, permanent VDOPS unit was purchased and installed

-

The plant achieved an ROI in under two months, with minimal ongoing consumable costs

Conclusion

BioKem’s VDOPS solution provided a cost-effective, safe, and efficient way to eliminate entrained gas contamination in the gas compressor’s lube oil system—without operational disruption.

If your facility faces similar contamination or maintenance challenges, contact BioKem Oil Services to learn how we can help extend your equipment’s life while saving costs.