Stop! Don’t Blend Your Lube Oils Until You Have Read This

You may not realise it, but older machines often have blended oils. If your machine is several years old, its oil likely mixes different oil groups. Many Group I oils have been phased out by oil companies. They were replaced with improved Group II formulations that often carry similar labels. Topping up lube oil with these formulations can lead to unintentional blending. This can harm your equipment, so it’s important to understand these issues.

Understanding Oil Groups: What’s the Difference?

Mineral oil is a natural resource derived from the earth. It forms over millennia from decomposed organic material. Crude oil is refined to create a base stock. This base stock is then blended with additives to develop lubricants tailored to specific applications.

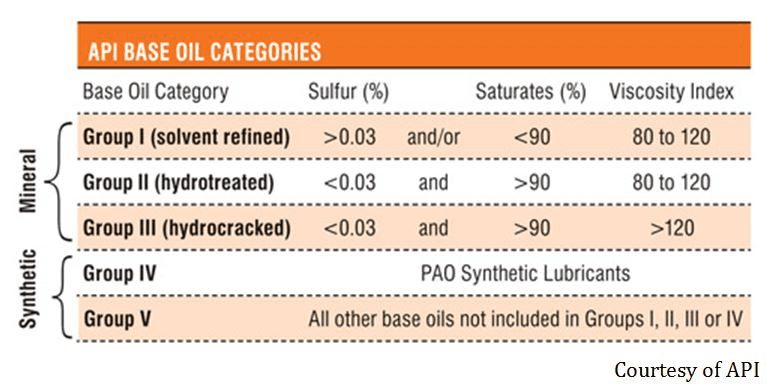

The degree of refining significantly impacts the oil’s properties. More intensive refining usually results in improved performance. Mineral oils are categorized into Group I, II, and III, with Group I being the least refined.

In contrast, synthetic oils are man-made. They fall into Group IV and Group V. Synthetic oils are generally more expensive than mineral oils but offer a significantly longer service life.

The development of synthetic lubricants arose from the need for better performance. This was especially true in environments where crude oil was scarce, such as wartime Germany. Aviation was one of the first industries to adopt synthetic oils. These oils outperform mineral oils during cold starts and in cold climates.

Synthetic oils also have a higher Viscosity Index. This means they maintain better viscosity stability across varying temperatures.

Group IV synthetic oils are produced from PAO’s (polyalphaolefins). Group V oils consist of various synthetic molecules, including polyesters, phosphate esters, di-esters, and alkylated benzenes. Each type offers specialized properties for different industrial applications.

Comparing Oil Groups: What’s Inside?

Another way to compare oil refinements is to visualize it as a fluid with suspended balls of varying sizes. The lower the Group level of the oil, the greater the variety of ball sizes and shapes. These represent different types of molecules.

Group I oils contain millions of differing atomic compounds. As oil is refined, it becomes more uniform. This results in ‘balls’ of similar size. In contrast, synthetic oils consist of only one size of ball.

Group I Oil – millions of compounds |

Group IV & V – Synthetic Oil |

Oil Clarity and Sulphur Levels

The brown color in oil primarily indicates its sulphur content. As you move up the Group levels, the sulphur content decreases, resulting in clearer oil—sometimes as clear as water, like baby oil.

Group III oil may be referred to as ‘synthetic,’ but it is not truly synthetic; it simply behaves more like synthetic oil.

Oil Blending: Availability and Consequences

With the phase-out of Group I oils due to technological advancements, Group II oils have become more affordable and widely available. However, blending Group I with Group II oils can lead to contamination and oxidation, reducing performance and causing varnish buildup.

Group I oil is now unavailable in lighter grades. As a result, industries often top up Group I lube compartments with Group II oils, hoping for compatibility. In-service Group I oil may contain waste by-products of oxidation. This occurs due to depleted antioxidants, which are a primary cause of varnish. It may also have other contaminants, like wear metals and environmental pollutants.

Adding ‘make-up’ Group II oils introduces new antioxidants. However, these can be quickly depleted by the existing Group I oil. This leads to further varnish potential as waste by-products accumulate.

Before adding Group II oil to your Group I oil, consult your supplier for compatibility. Ensure that your Group I oil is clean and free of contaminants. Check that it has sufficient antioxidants or remaining useful life. Confirm whether mixing is truly necessary. It’s also wise to conduct an RPVOT Oxidation test with your lab.

Warning: If your Group I oil is beyond recovery (oxidized), do not try to rejuvenate it by adding Group II oil. Instead, drain and flush your system. Then, add a fresh charge of Group II oil.

Rotating pressure vessel oxidation test (RPVOT) – ASTM D2272, formerly called the rotating bomb oxidation test (RBOT)

Rotating pressure vessel oxidation test (RPVOT) – ASTM D2272, formerly called the rotating bomb oxidation test (RBOT)

The Twisty Turny Bit

Blending oils can mislead laboratory results. This may make it seem that antioxidant levels are acceptable. In reality, the new Group II oil skews the readings.

Keep this in mind and look for other indicators, such as visual varnishing and staining. If you’re uncertain, inspect the oil cooler elements on the off-duty unit. Staining indicates that the oil has broken down and is shedding its additive package.

You may need to remove the blended oil. Treat the varnish, flush the system, and replenish with new polished Group II oil.

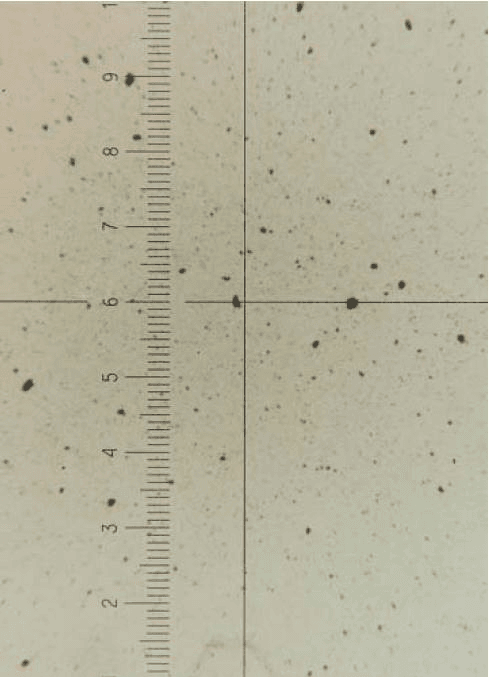

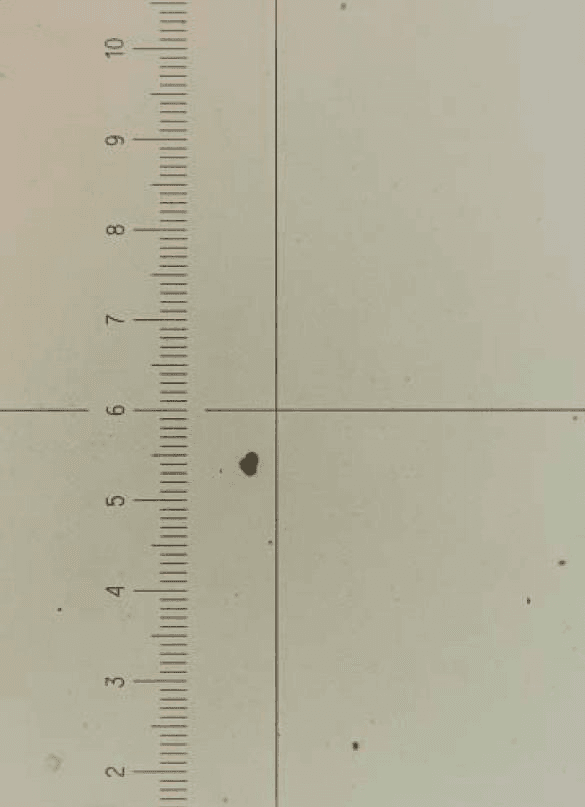

Tip: Ensure your new oil is polished (filtered) before use. It may not meet equipment OEM cleanliness (ISO 4406) standards when supplied by the oil reseller!

ISO 20/18/16 NAS 10 – sample from ‘new’ oil delivered in a tote |

ISO 15/12/10 NAS 4 – Polished with 2μm microglass media |

Pros and Cons of Oil Groups

Group I Oils:

- Pros:

- Historically cheap and readily available.

- Greater tolerance to particle and water contamination.

- Cons:

- Degraded Group I oil can change its molecular structure and become carcinogenic.

Group II Oils:

- Pros:

- Readily available and affordable.

- Can withstand higher operating temperatures.

- Increased service life, better wear protection, and improved lubricity.

- Cons:

- Lower threshold for varnish-causing contaminants.

Group III Oils:

- If you manage clean oil, moisture, and particulates effectively on your site, Group III oils can provide superior wear protection and an improved Viscosity Index for your machines.

Managing Oil Cleanliness: Best Practices

Many solutions are available today to reduce moisture and particulate contamination. BioKem offers a range of units for this purpose. For optimal results, consider a VDOPS vacuum dehydrator.

These units effectively remove dissolved, free, and emulsified water. They also eliminate entrained gas and particulates from heavy gear oils to very light oils of any Group. VDOPS units are regarded as the gold standard in the filtration industry. They feature class-leading microglass filtration media that removes particles as small as 2μm.

If you need advice on specifying or sizing a suitable unit for your plant, please let us know.

Conclusion: Avoid Blending—Drain, Flush, and Refill

Avoiding ad hoc mixing or blending of old and new oils will benefit your lube circuits and rotational equipment. In critical, close-tolerance rotating equipment, the risks of blending are simply not worth it.

If possible, Don’t blend – Drain, Flush, Polish and Refill!

If you would like further information on this article or others, please feel free to contact us.